Ever notice how a stop sign seems to leap out of the darkness, brightly illuminated by your car’s headlights? That is not a happy accident. It is the result of safety technology built for a purpose, known as a reflective sign. These signs are engineered with special surfaces that catch and return light, making them highly visible in conditions with low light without needing their own power source.

Instead of using electricity, a reflective sign is coated in a material called retroreflective sheeting. This remarkable film bounces a vehicle’s headlight beams directly back toward the driver’s eyes. It is a simple but brilliant solution that ensures the shape, color, and message of a traffic sign are clear day or night. Modern reflective signs use powerful films with tiny glass beads or microprisms, allowing drivers to see them from hundreds of feet away.

How Retroreflectivity Makes Signs Shine

The core principle that makes a reflective sign work is called retroreflectivity. It is a unique optical property that causes a surface to return light directly to its source with very little scattering. Think of it as a smart mirror. When your headlights hit the sign, the retroreflective material gathers that light and shoots it right back at you, the driver. This is why the sign appears brightest to the person sitting behind the light source.

To really get it, it helps to know what it is not. Retroreflection is very different from the two other common ways surfaces reflect light.

Diffuse Reflection (Why Paint Is Not Enough)

Diffuse reflection happens when light hits a rough or matte surface, like a piece of paper or a painted wall. The light scatters in every direction. While this is great for seeing things evenly in daylight, it is terrible for nighttime visibility. A sign with a normal painted surface would scatter your headlight beams everywhere, with only a tiny fraction of that light returning to your eyes. This is why early road signs were nearly invisible after dark unless they had their own lamps.

Mirror Reflection (Why Shiny Can Be a Problem)

Mirror reflection, or specular reflection, is what you see from a very smooth, shiny surface. It follows a simple rule: the light bounces off at the same angle it came in. If a traffic sign were a perfect mirror, it would likely reflect your headlights off to the side of the road, completely missing you unless you were at the exact right angle. It could also create dangerous glare. A reflective sign avoids this by using retroreflection to send light back to its origin, not off in another direction.

The Critical Role of Reflective Sheeting for Road Safety

Good nighttime visibility is the entire point of a reflective sign, and its impact on safety is massive. Driving at night is inherently more dangerous. While only about 25% of driving occurs after dark, this period accounts for roughly 50% of all traffic fatalities. Using high quality reflective sheeting for road safety directly combats this risk.

Improving the visibility of a reflective traffic sign can lead to significant safety improvements.

- One city saw an incredible 38% drop in crash rates after upgrading its signs.

- Another study found that enhancing just the reflectivity of stop signs reduced nighttime crashes at those intersections by 4.4%.

This is not just for traffic safety. For a business, being seen at night is crucial for attracting customers. A beautifully designed storefront sign that disappears after sunset is not working as hard as it could be. Design led options like the Round Outdoor Shop Sign pair well with reflective vinyl so your branding stands out after dark. By incorporating reflective elements, a café or boutique can ensure its branding remains bright and welcoming, guiding customers to its door long after dark.

A Guide to Reflective Sheeting Types

The workhorse behind every reflective sign is the sheeting applied to its surface. This film comes in several grades, categorized by their brightness and construction, often according to standards like ASTM D4956. The main difference lies in the technology used, either microscopic glass beads or advanced microprisms.

Engineer Grade (Type I): The Original Standard

Engineer Grade is the classic reflective sheeting, first introduced in 1939. It uses tiny glass beads embedded in a resin layer to bounce light back. For decades, this was the preferred material for road signs and is still a great, affordable option for non critical applications like parking signs or building markers. It typically has a service life of about 5 to 7 years. However, due to its relatively modest brightness, many highway agencies have phased it out for new road signs in favor of newer, more powerful options.

High Intensity Prismatic (HIP): The Modern Workhorse

High Intensity Prismatic sheeting represents a major leap forward in technology. Instead of glass beads, it uses microscopic prisms to reflect light far more efficiently. A HIP sign can be several times brighter than its Engineer Grade counterpart, dramatically improving visibility in rain or darkness. It offers a fantastic balance of performance, durability (around 10 years), and cost, which is why many cities now use it as the standard for most street and highway signs.

Diamond Grade (Type IX/XI): The Brightest and Best

When maximum visibility is non negotiable, Diamond Grade sheeting is the answer. This is the highest tier of material, using highly efficient microprisms with a full cube design. This advanced optical design is so effective it can return nearly 60% of available headlight beams back to the driver. The practical result is a sign that is exceptionally bright and can be read from very long distances. Early prismatic prototypes showed a sign that was barely visible at 300 feet with old material could be legible at 3,000 feet with the new technology. Diamond Grade is often required for critical highway signs, overhead freeway guides, and warnings in high risk areas.

The Best Base for Brilliance: Reflective Aluminum Signs

While the sheeting provides the sparkle, the sign’s base material provides the strength. For a reflective sign to be effective and long lasting, it needs a durable and weather resistant foundation. This is why a reflective aluminum sign is the industry standard for nearly all official road and traffic signs.

Aluminum offers several key advantages.

- Durability: It is strong enough to withstand harsh weather conditions without bending or breaking.

- Corrosion Resistance: Unlike steel, aluminum does not rust, ensuring the sign remains structurally sound and visually clean for years.

- Lightweight: It is easy to transport and install, reducing labor costs.

These same qualities make aluminum an ideal choice for commercial signage. It provides a premium, lasting canvas that ensures your investment continues to look great and perform well over time.

From Highways to Your Storefront: Applying the Technology

Understanding the power of a reflective sign is key, whether you are navigating a dark highway or trying to make your business stand out. The same principles that make a stop sign pop can be applied to commercial signage to boost visibility and attract attention.

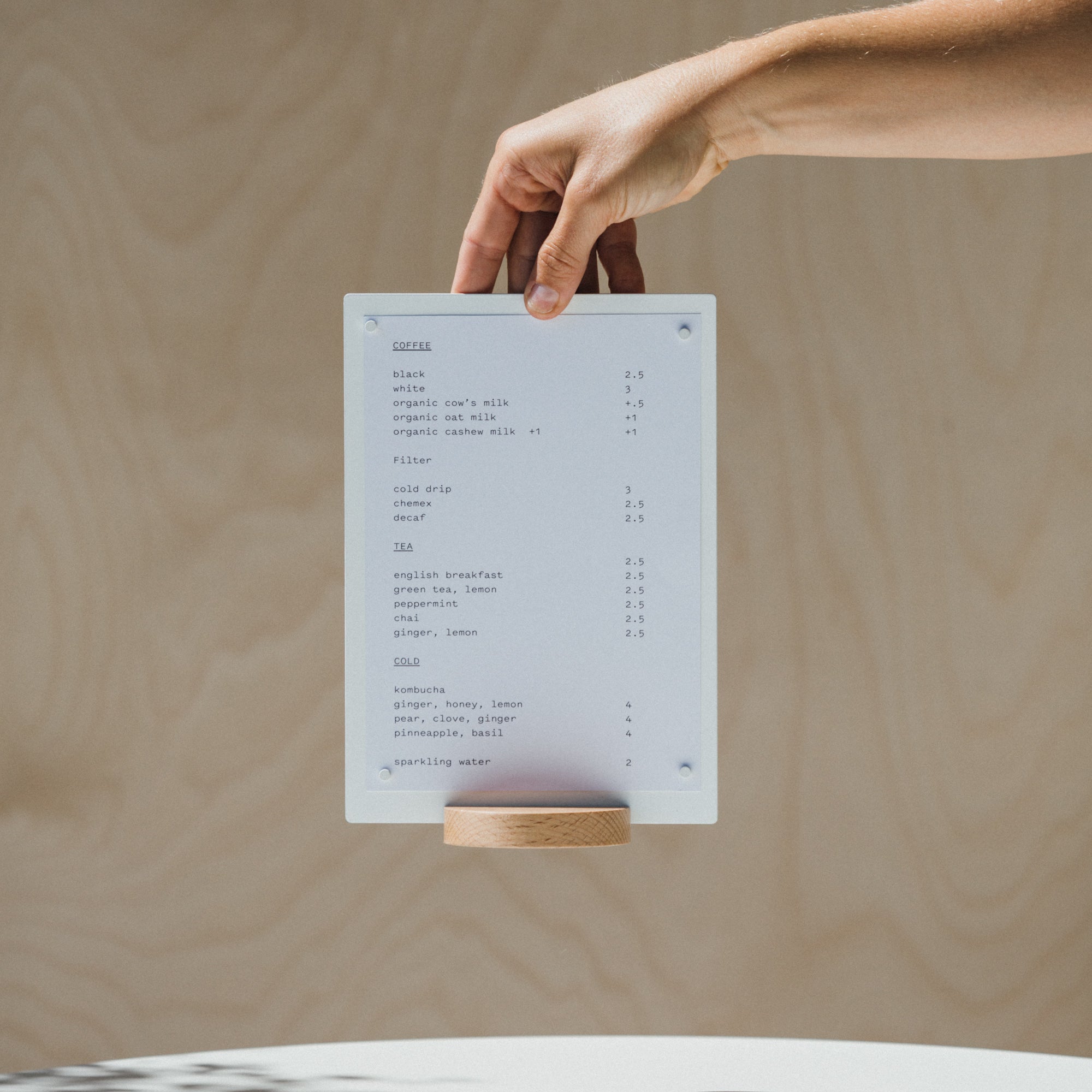

While the signs you see on the side of the road are built for regulatory compliance, the underlying technology is available for everyone. A beautifully crafted, minimalist sign (like the Standing Signs) provides the perfect blank canvas. By applying custom cut reflective vinyl lettering or logos, a business can transform its daytime sign into a brilliant nighttime beacon. This ensures your brand’s first impression is just as strong and clear at 9 PM as it is at noon.

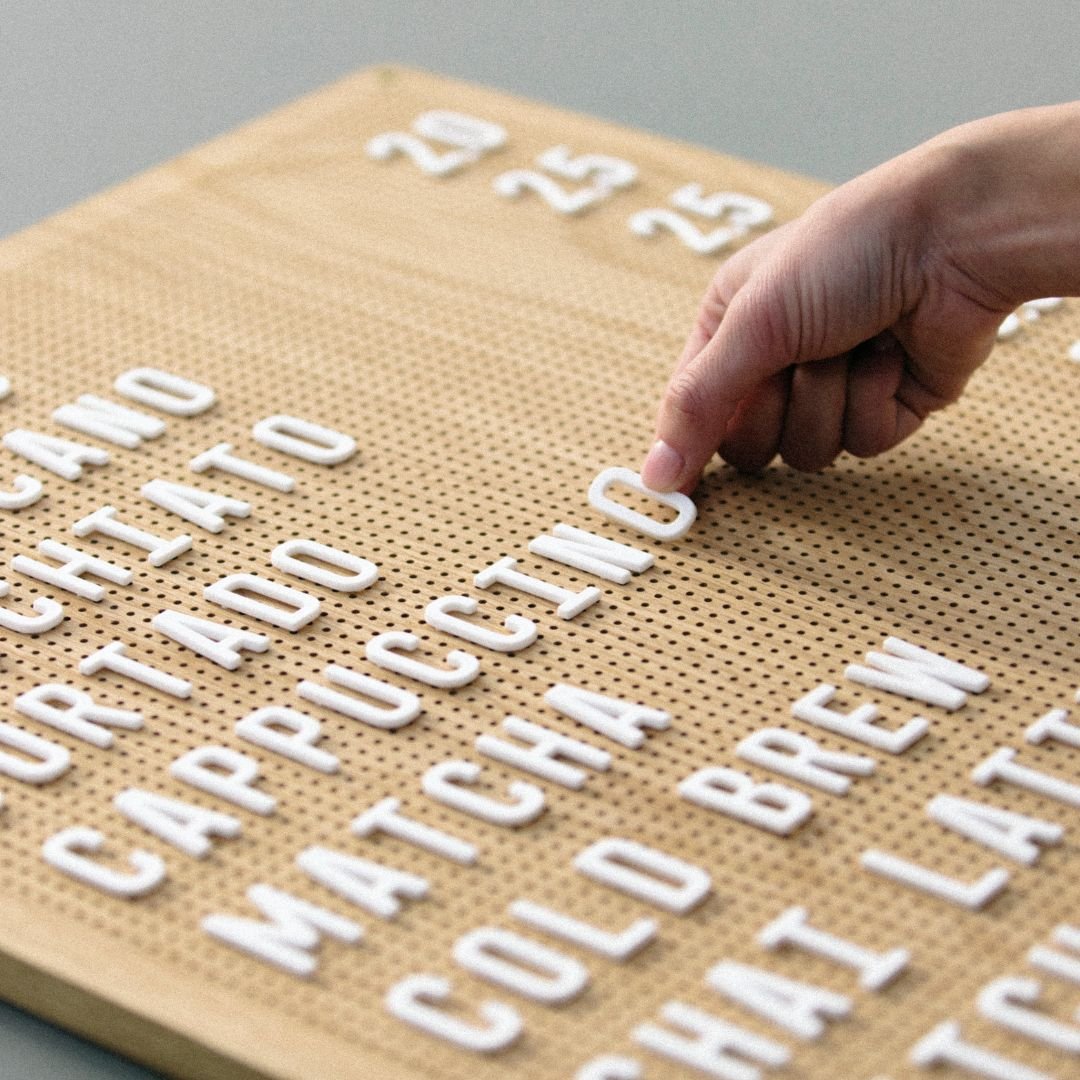

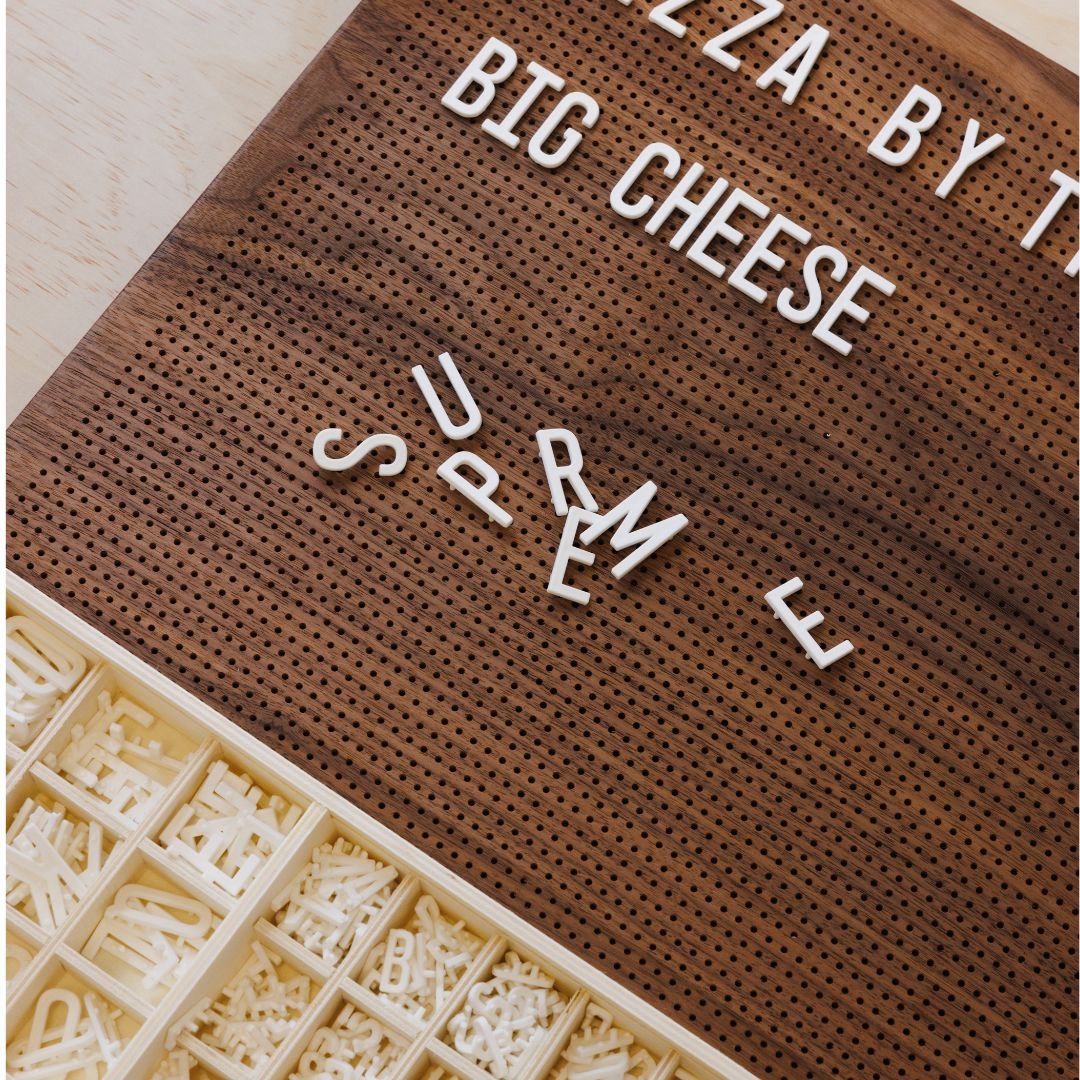

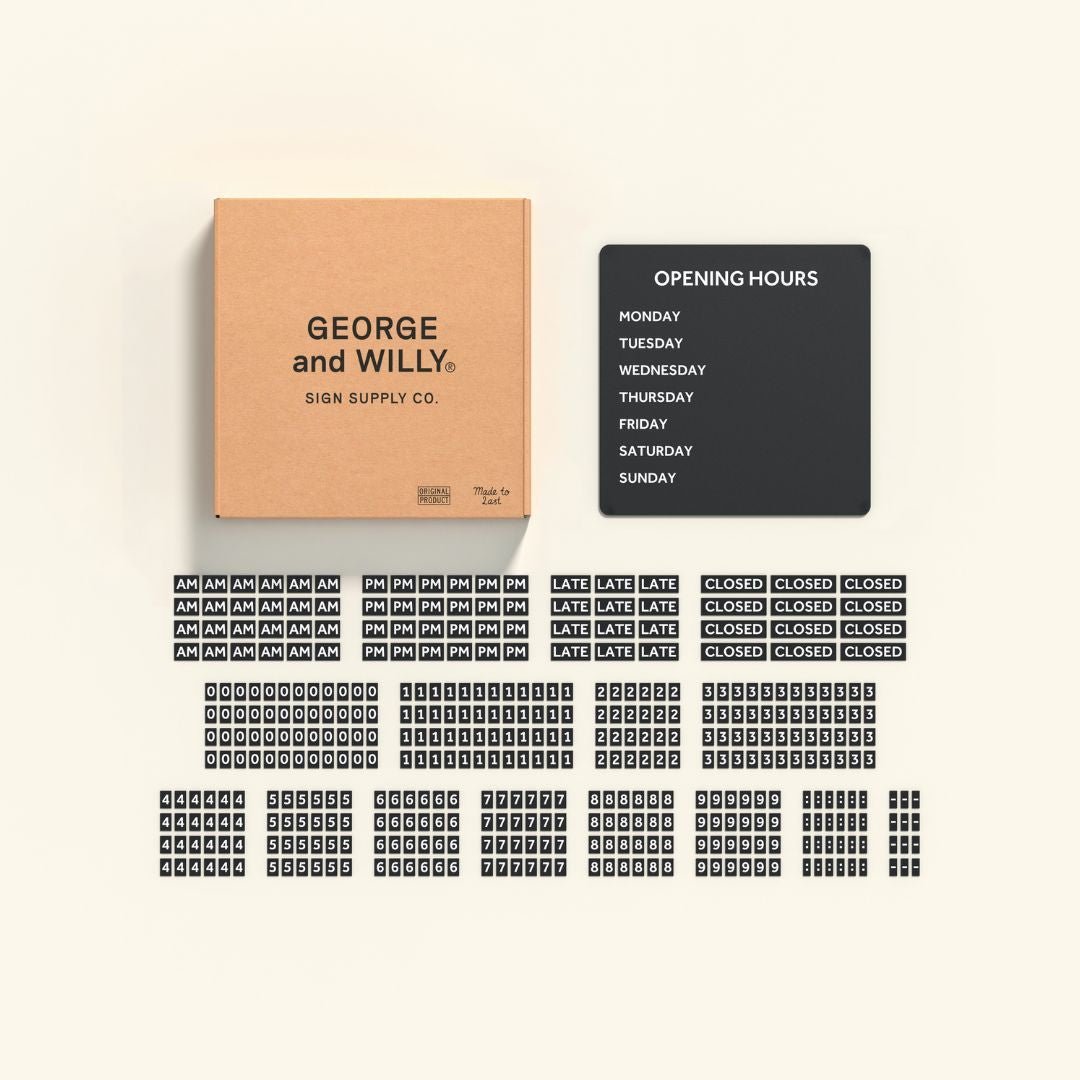

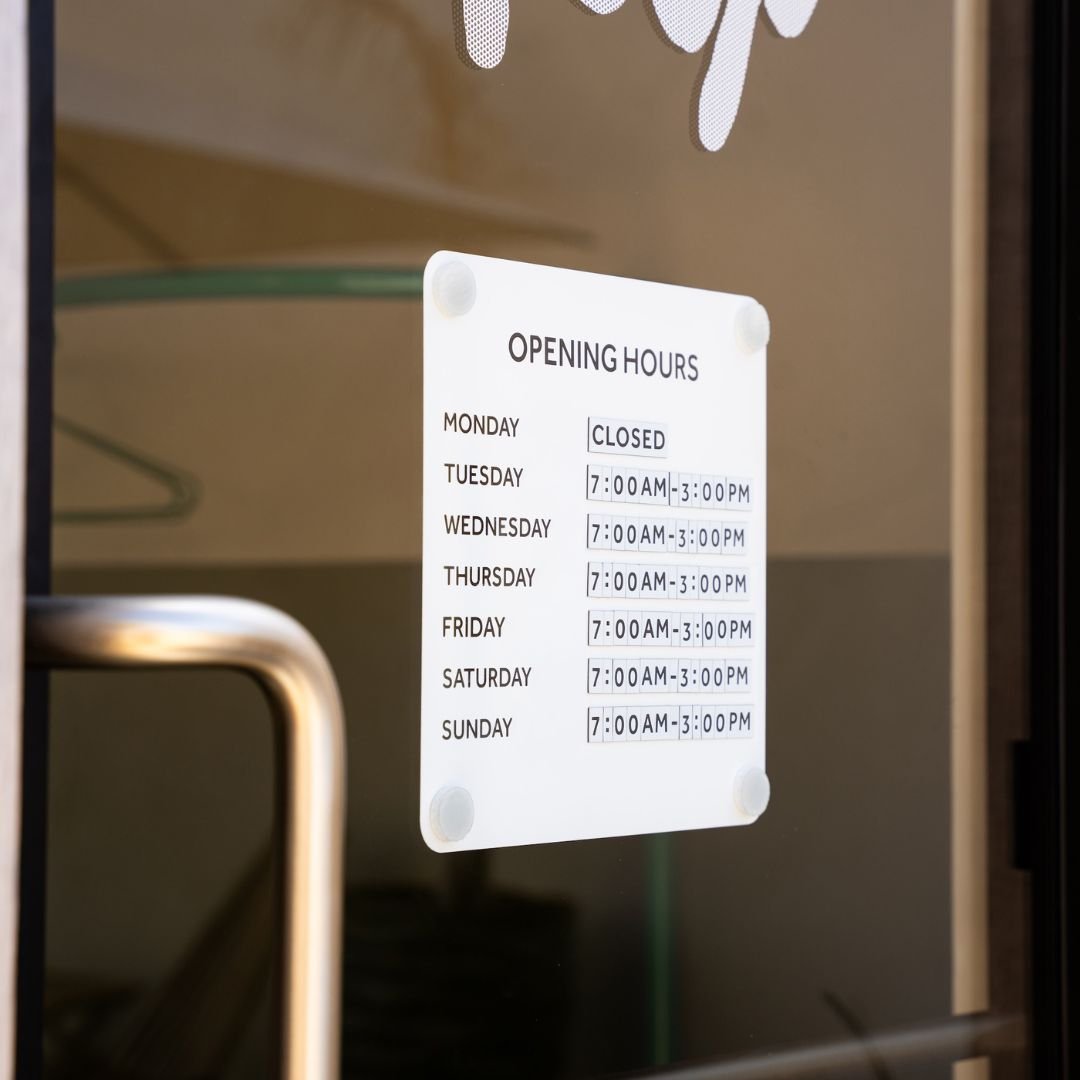

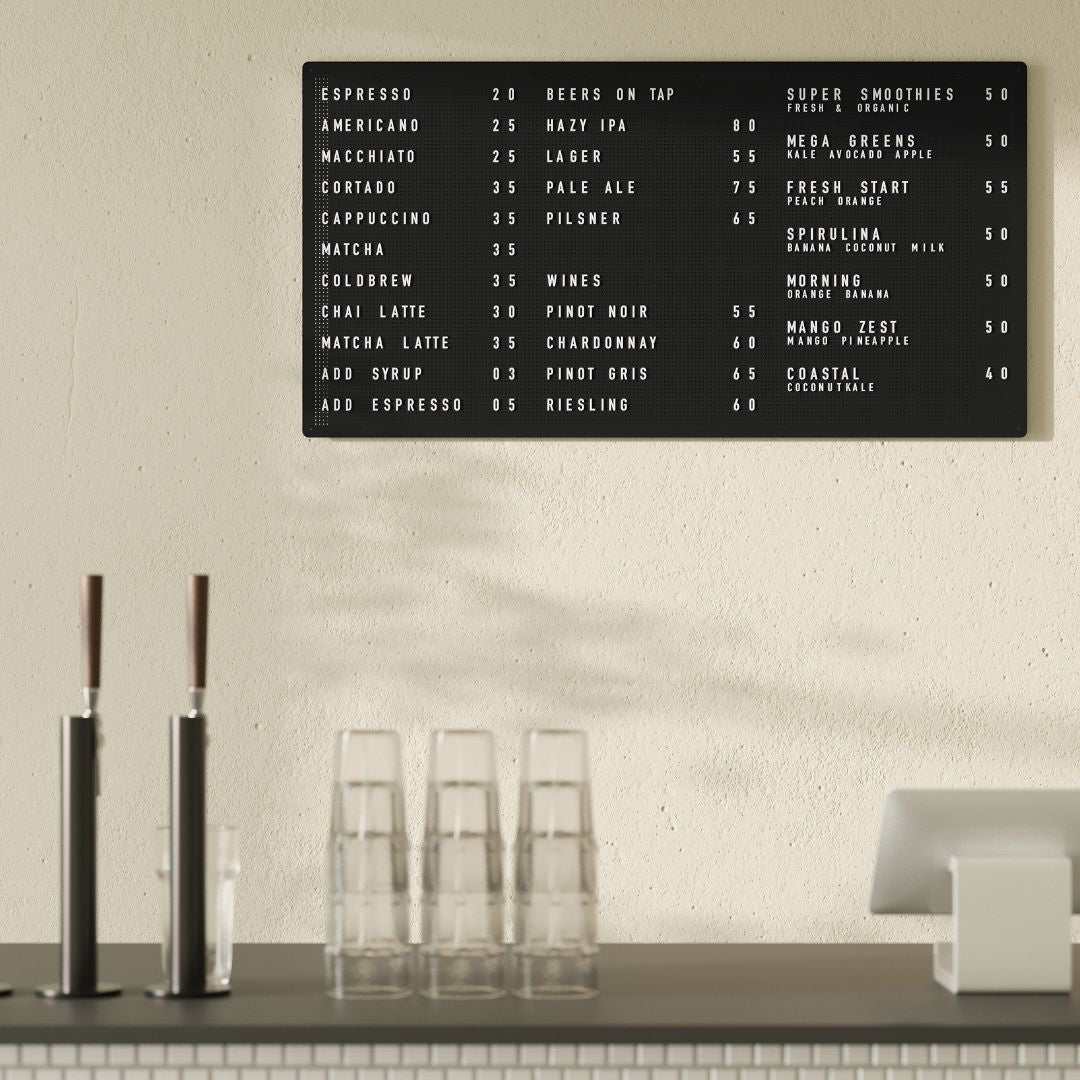

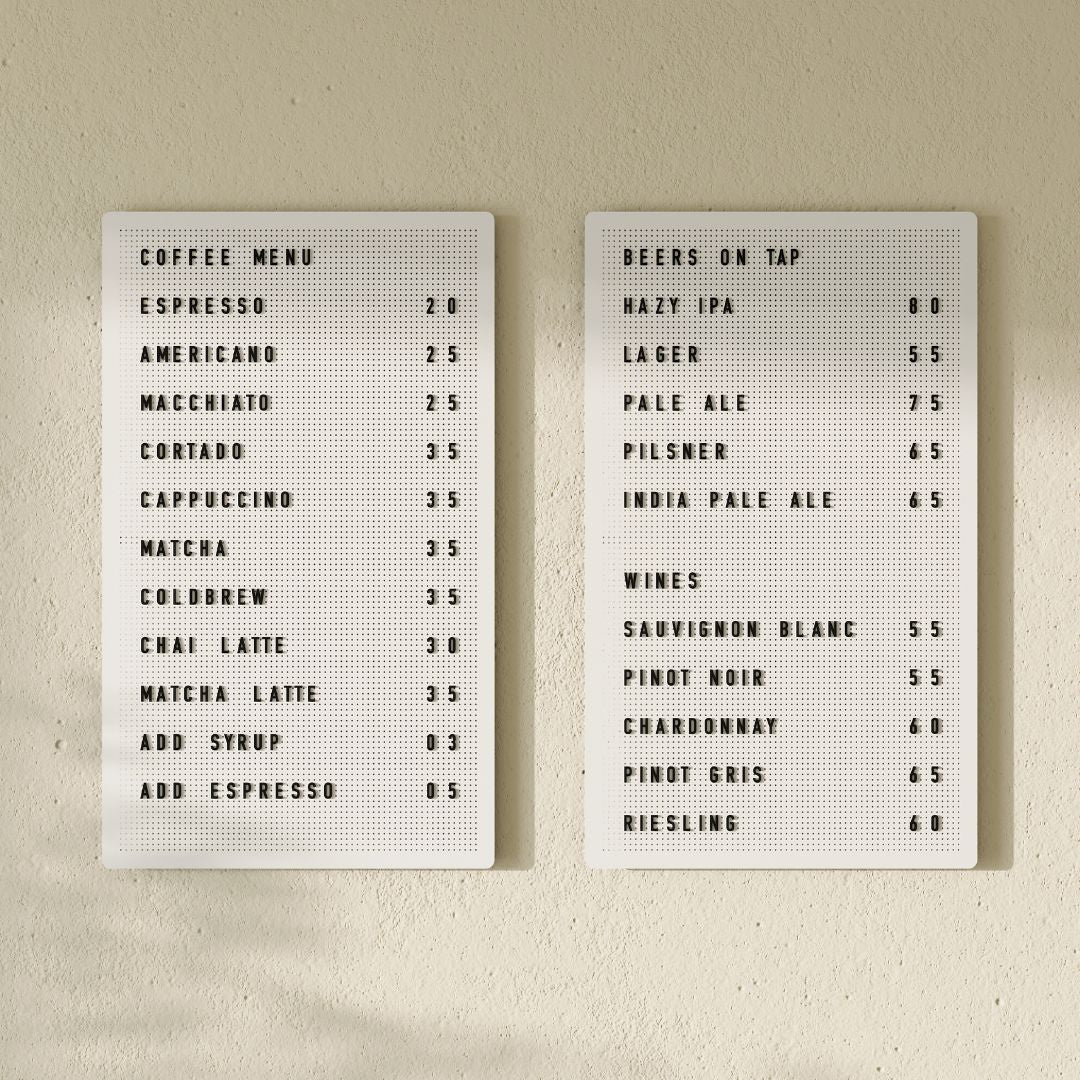

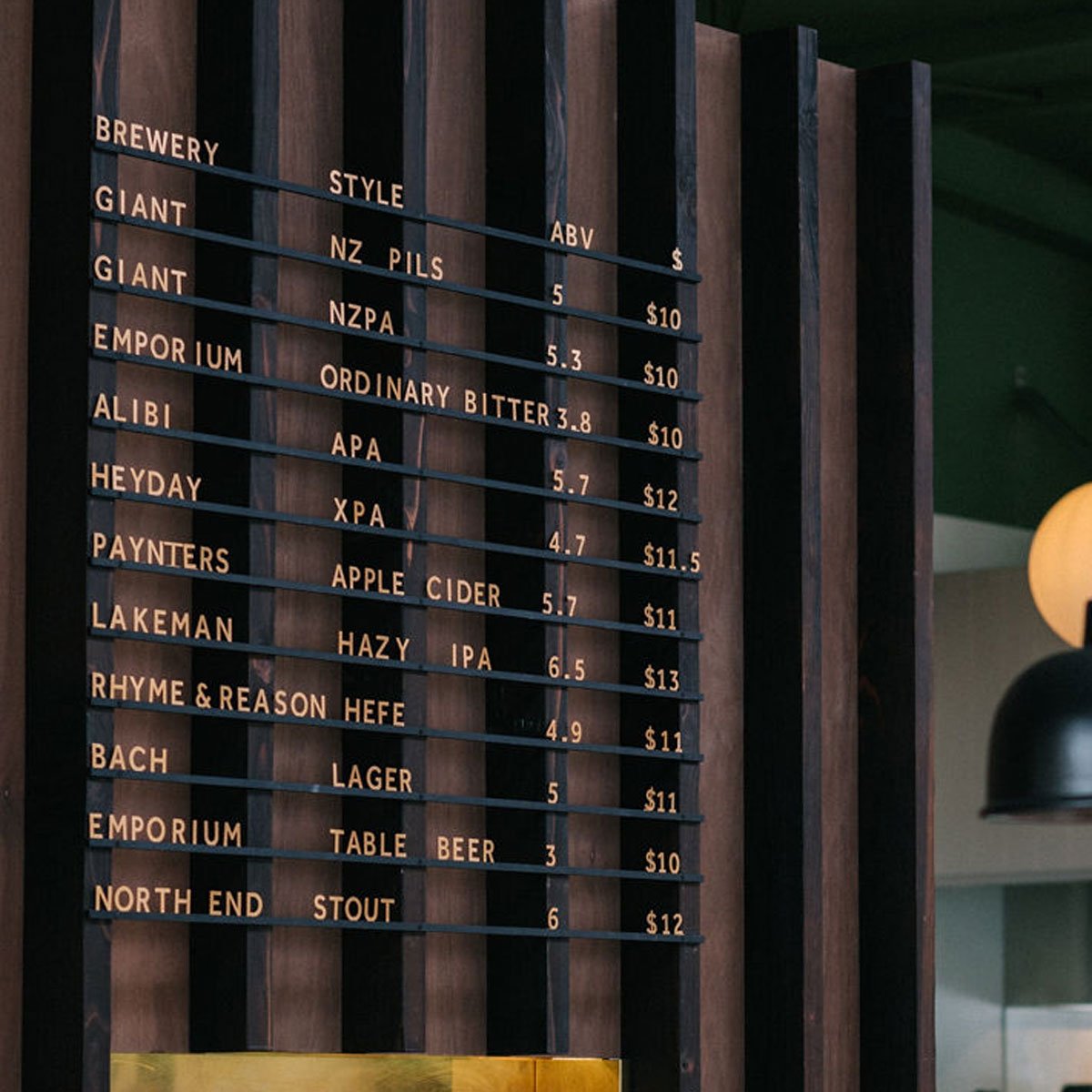

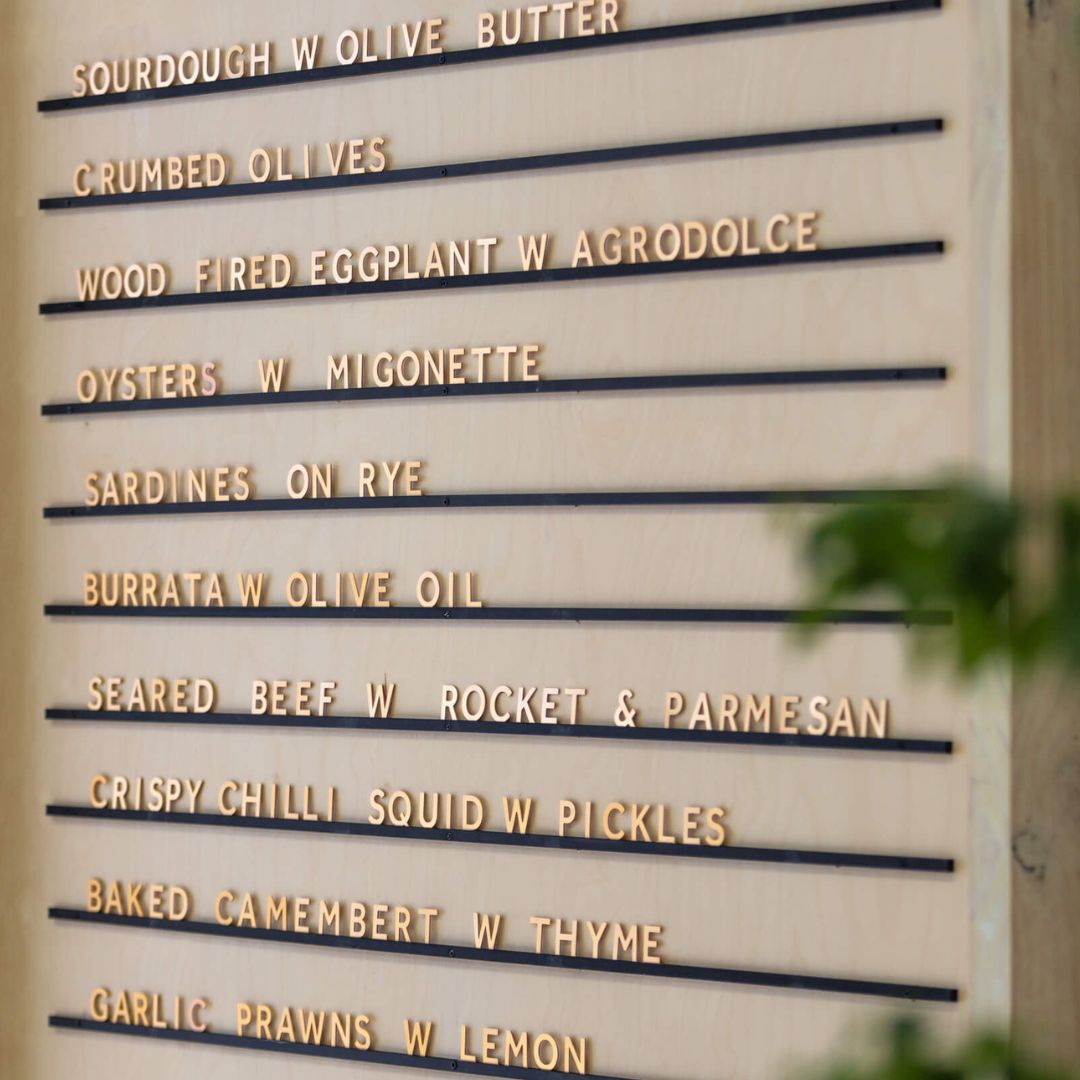

Inside, pair your exterior sign with a Letter Menu Board for fast menu updates that stay legible under low light. If you are looking for signage that blends timeless design with practical function, check out options like the Store Sign from George & Willy.

Creating a cohesive and inviting look for your space is simple when you start with a strong foundation. A well made Business Sign or Wall Sign can be easily enhanced for nighttime visibility, helping you do better business. Explore pieces like the Rounded Sidewalk Sign to find the perfect starting point for your brand.

A Brief History of the Reflective Sign

The journey from a painted piece of wood to today’s high technology reflective sign is a fascinating story of innovation driven by the need for safety.

- Before the 1920s: Road signs were simple painted boards, virtually useless at night.

- 1920s: The first breakthrough came with reflector “buttons” or “cat’s eyes,” small glass reflectors embedded into sign letters to make them glow.

- 1930s: 3M engineer Harry Heltzer developed the first true reflective sheeting, branded Scotchlite. By embedding glass beads onto an adhesive film with a metallic backing, he created a surface that could illuminate an entire sign.

- 1940s: Reflective sheeting became the preferred solution during WWII blackouts. By 1948, U.S. standards mandated that all important warning and regulatory signs must be lit or reflectorized.

- 1970s: The next revolution arrived with microprismatic technology developed by a company called Reflexite. This new method using tiny prisms was up to 20 times brighter than the old glass bead films.

- 1990s to Today: Prismatic technology became the industry standard. 3M introduced its popular Diamond Grade sheeting, and competitors followed suit. Today, nearly all official road signs use some form of prismatic reflective sheeting, a technology that has undoubtedly saved countless lives.

Frequently Asked Questions for More Reflective Sign Information

What makes a reflective sign “glow” at night?

A reflective sign does not produce its own light. It uses a special surface called retroreflective sheeting that bounces light from a source (like car headlights) directly back to the viewer’s eyes, making it appear brightly lit.

What are the main types of reflective sign material?

The three most common types are Engineer Grade (using glass beads), High Intensity Prismatic (using microprisms), and Diamond Grade (using the most efficient microprisms). Each offers a different level of brightness and durability.

Why are most traffic signs made of aluminum?

Aluminum is the preferred material for a reflective aluminum sign because it is durable, lightweight, and naturally resistant to rust and corrosion. This ensures the sign has a long service life in all weather conditions.

Can I make my own business sign reflective?

Absolutely. You can start with a high quality blank sign, like an aluminum A Frame or Vertical Blade Sign, and have a local signwriter apply custom graphics using reflective vinyl. This gives you a professional, durable sign that is visible day and night.

What is the difference between reflective and glow in the dark?

Reflective materials need an external light source (like headlights) to work. They reflect that light. Glow in the dark materials absorb energy from a light source and then slowly release it, glowing on their own for a period of time in complete darkness.

How long does a reflective sign last?

The lifespan depends on the grade of the sheeting. Engineer Grade typically lasts 5 to 7 years, High Intensity Prismatic lasts around 10 years, and premium Diamond Grade can last 12 years or more.