First impressions are everything, especially for a physical business. Before a customer tastes your coffee or tries on your clothes, they see your sign. It’s your 24/7 salesperson, your brand ambassador, and your first handshake all rolled into one. Understanding the world of manufacturing signs helps you make a choice that not only looks good but also works hard for your bottom line.

A great sign can stop people in their tracks, communicate your brand’s personality, and even drive sales. In fact, research shows that about 76% of consumers have entered a store they had never visited before simply because the signage caught their eye. This guide explores the essentials of manufacturing signs, from materials and types to the legal requirements and design principles that deliver a real return on investment.

The Sign Manufacturing Process: From Concept to Installation

At its core, the process of manufacturing signs involves a few key stages. It starts with a concept and design, where the sign’s message, branding, and look are decided. Next comes material selection, a crucial step that determines the sign’s durability and aesthetic. Fabrication is where the sign is physically built, cut, and assembled. Finally, finishing touches like powder coating or painting are applied before the sign is ready for installation.

Design and File Prep Best Practices

Before any material is cut, a solid design is essential. For business owners planning to add branding to a blank sign with a local signwriter, providing proper artwork is key.

- Use Vector Graphics: Logos and text should be in a vector format (like AI, EPS, or SVG files). This allows the design to be scaled to any size without losing quality or becoming pixelated.

- Keep it Simple: The most effective signs are often the simplest. A cluttered sign with too much information is hard to read, especially from a distance. Focus on your business name, logo, and maybe a single key message.

- Outline Fonts: Convert all text to outlines or curves. This ensures the font appears exactly as intended, even if the signwriter doesn’t have that specific font installed.

Choosing the Right Materials

The material used in manufacturing signs is just as important as the design. It affects longevity, appearance, and how well the sign represents your brand’s quality.

Durable Metals Like Aluminum and Steel

For outdoor signage, materials that can withstand the elements are essential. Aluminum and steel are top choices because they are strong, waterproof, and handle harsh weather well. Powder coated aluminum is particularly popular because it doesn’t rust and can last for years. Products in our shopfront sidewalk sign range keep a storefront looking sharp. A well made aluminum sign can survive outdoors for 7 to 10 years before showing significant wear. Stainless steel offers a sleek, modern aesthetic and is highly resistant to rust and corrosion, making it another premium choice for long lasting signs.

Classic Woods and Modern Composites

Wood offers a warm, classic aesthetic that works beautifully for many cafes and boutiques. However, it requires proper treatment and maintenance to prevent rot and decay outdoors. For a similar look with greater durability, High Density Urethane (HDU) is a waterproof and affordable alternative that can be carved to look like wood.

Other popular materials include:

- Acrylic: Known for its polished, glossy finish, acrylic is great for a modern look and is suitable for both indoor and outdoor use. It’s the go to material for illuminated signs.

- Aluminum Composite Material (ACM): This material combines the strength of aluminum with a lightweight polyethylene core, ensuring it stays flat and doesn’t warp.

- PVC: A lightweight and cost effective option, PVC is popular for indoor and temporary outdoor signs but can warp with prolonged sun exposure.

Key Types of Business Signs and Their Impact

The world of manufacturing signs offers a variety of options, each serving a unique purpose. Choosing the right type can dramatically influence customer behavior.

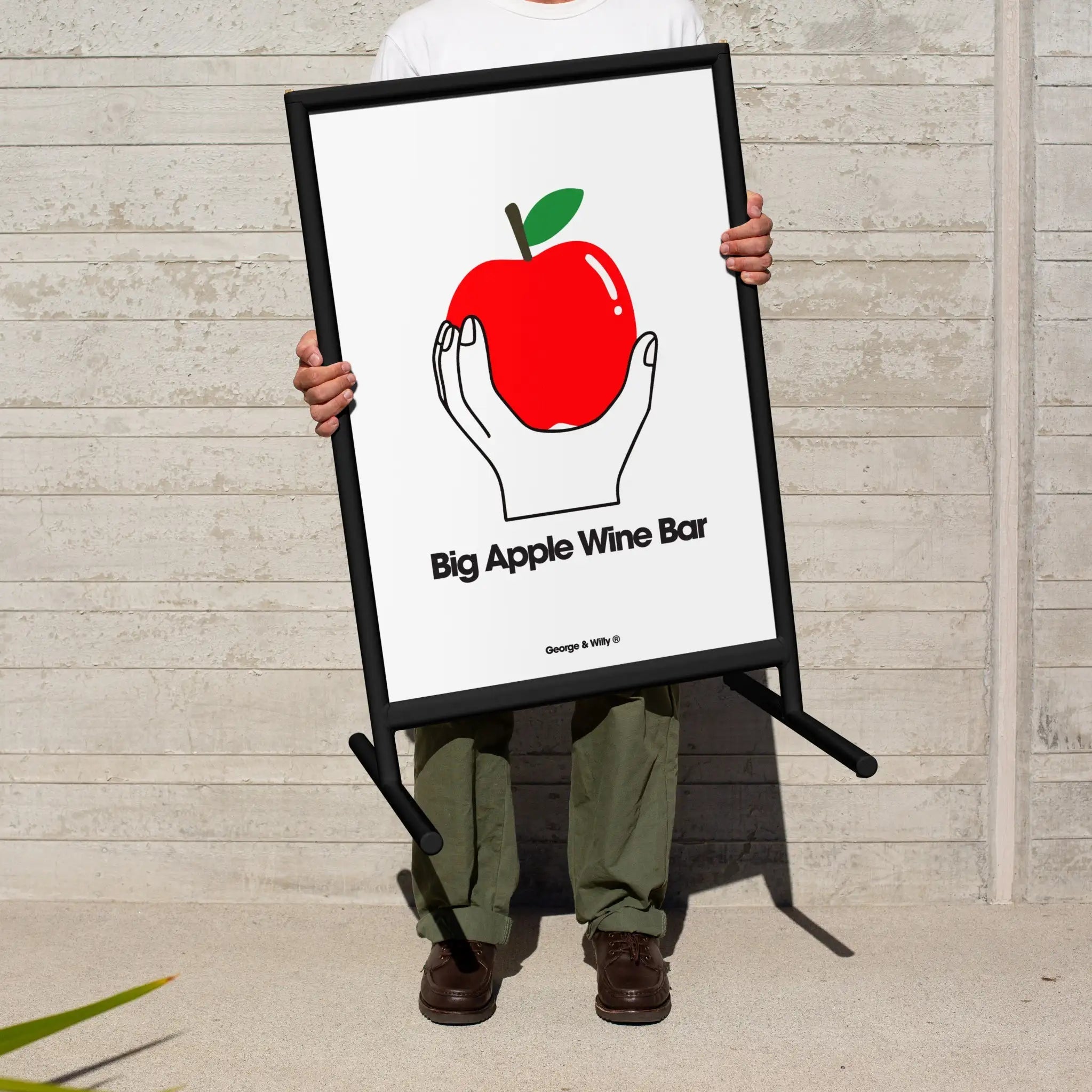

Curbside and Storefront Signs to Grab Attention

Your exterior sign is your primary tool for attracting foot traffic. A striking A-Frame Sign on the sidewalk or an elegant Blade Sign hanging above your door makes your business visible from down the street. The goal is to be seen and remembered. Since nearly 7 in 10 consumers have made a purchase because a sign caught their attention, investing in eye catching curbside signage is a smart move.

Interior and Point of Purchase Signage

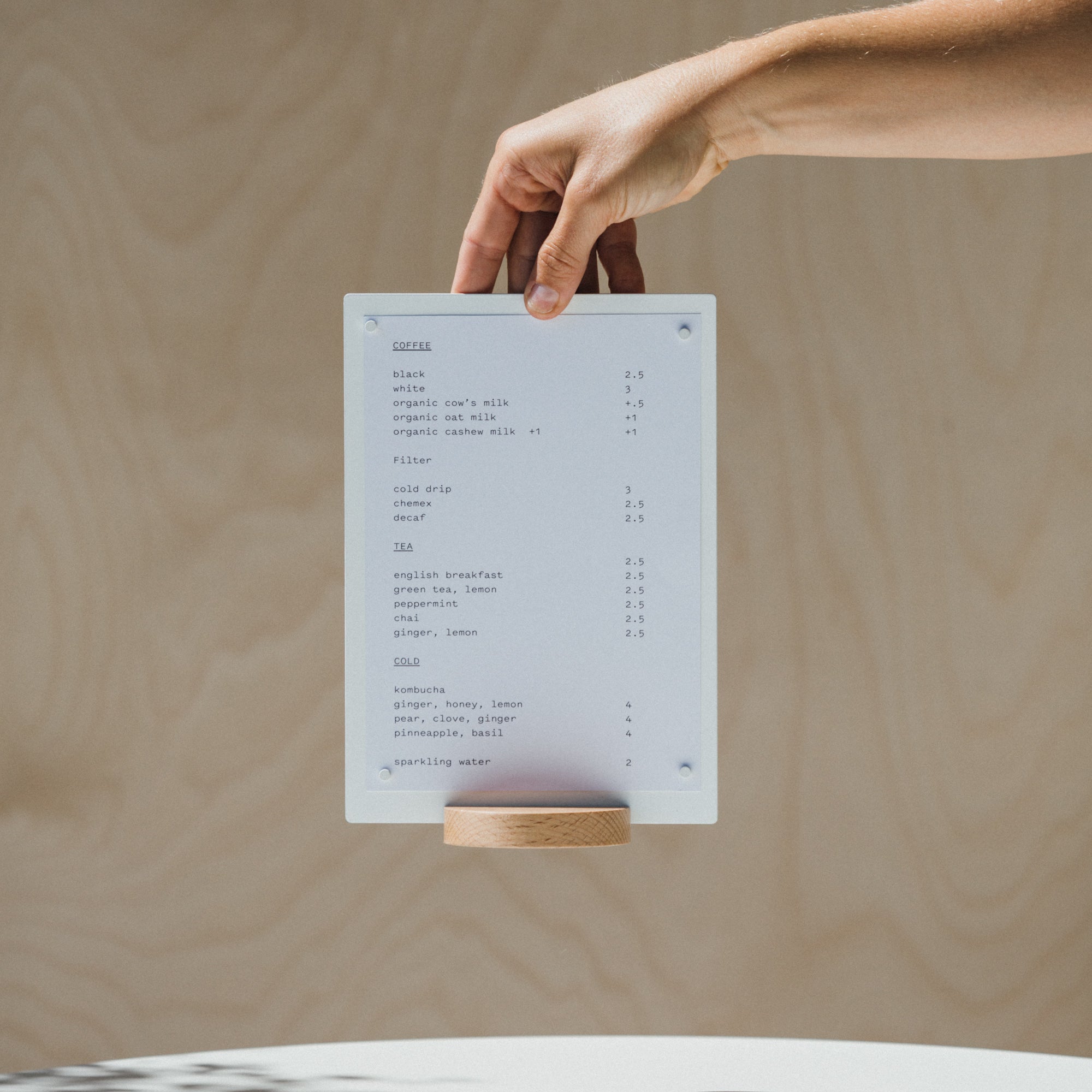

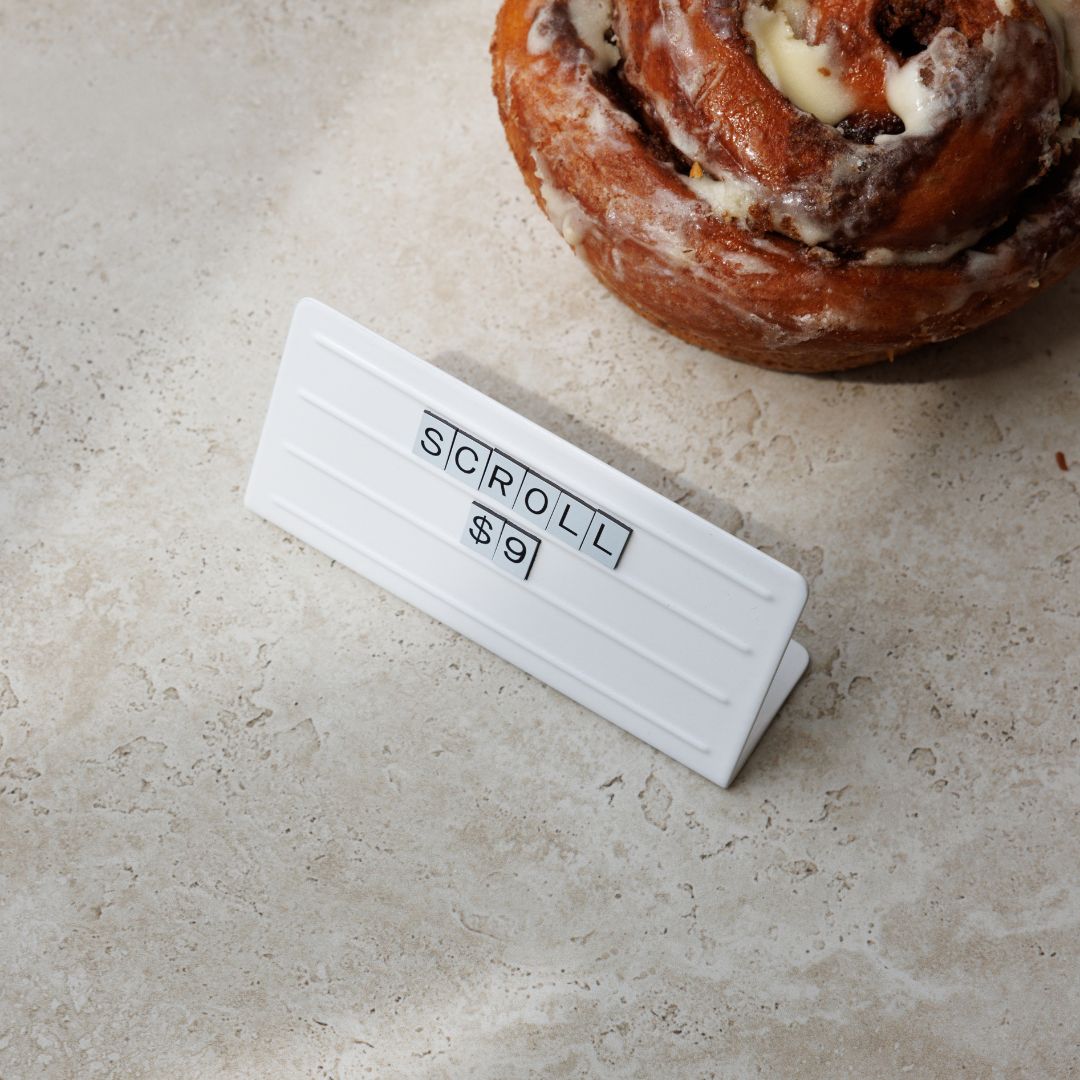

The job isn’t done once a customer walks inside. Interior signs guide the shopping experience and encourage additional sales. Strategically placed tabletop signs, Pricing Signs, and shelf talkers act as silent salespeople. In store signage, like Table Talkers highlighting specials at the register, can lead to a 60% increase in impulse purchases by showcasing best sellers or complementary items. Little prompts near the checkout, like Counter Signs, can make a big difference.

Wayfinding and Directional Systems

Effective wayfinding signage helps people navigate your space with confidence. This includes signs pointing to restrooms, exits, or different departments. A cohesive “sign family” that uses consistent fonts, colors, and materials across all wayfinding signs creates a professional and seamless customer experience.

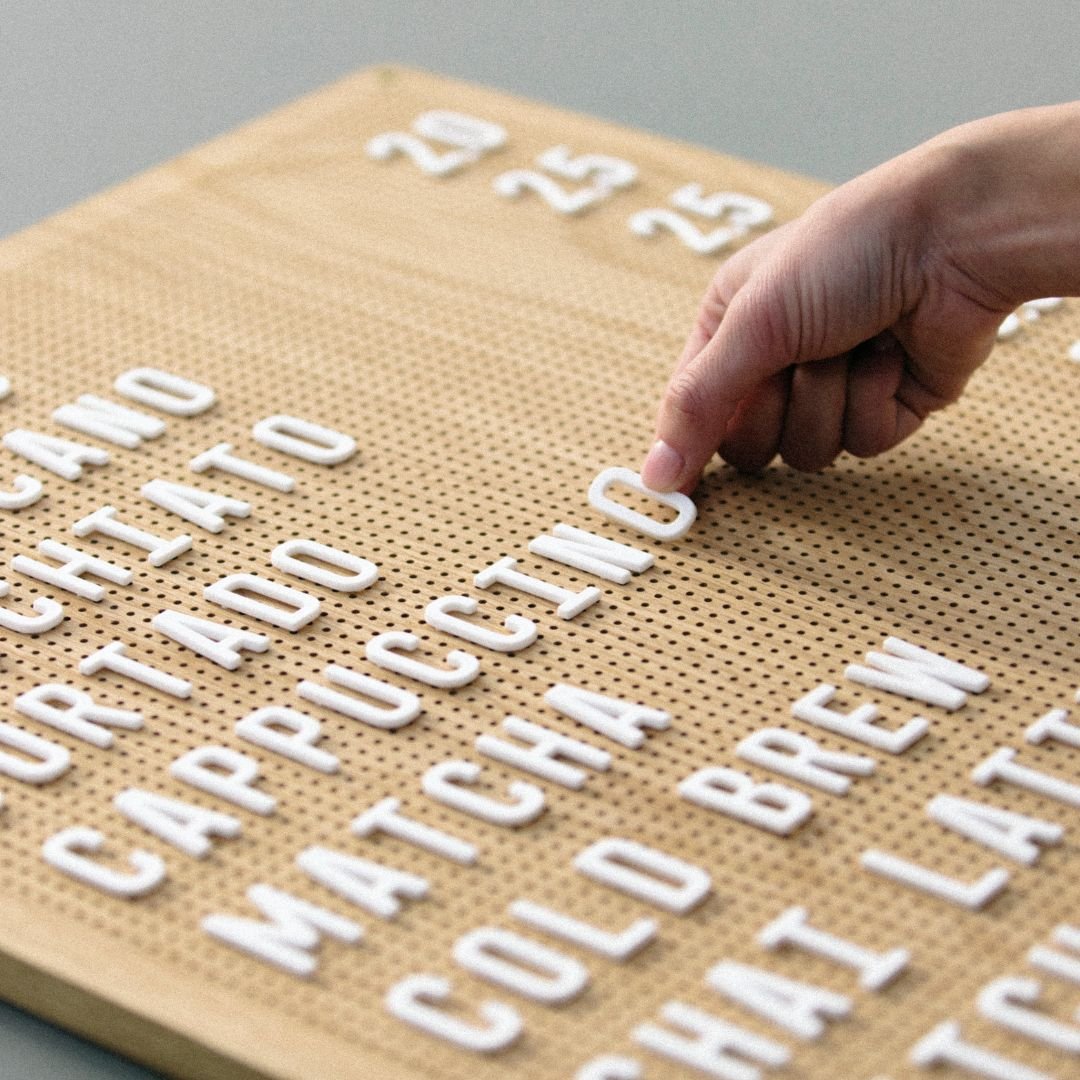

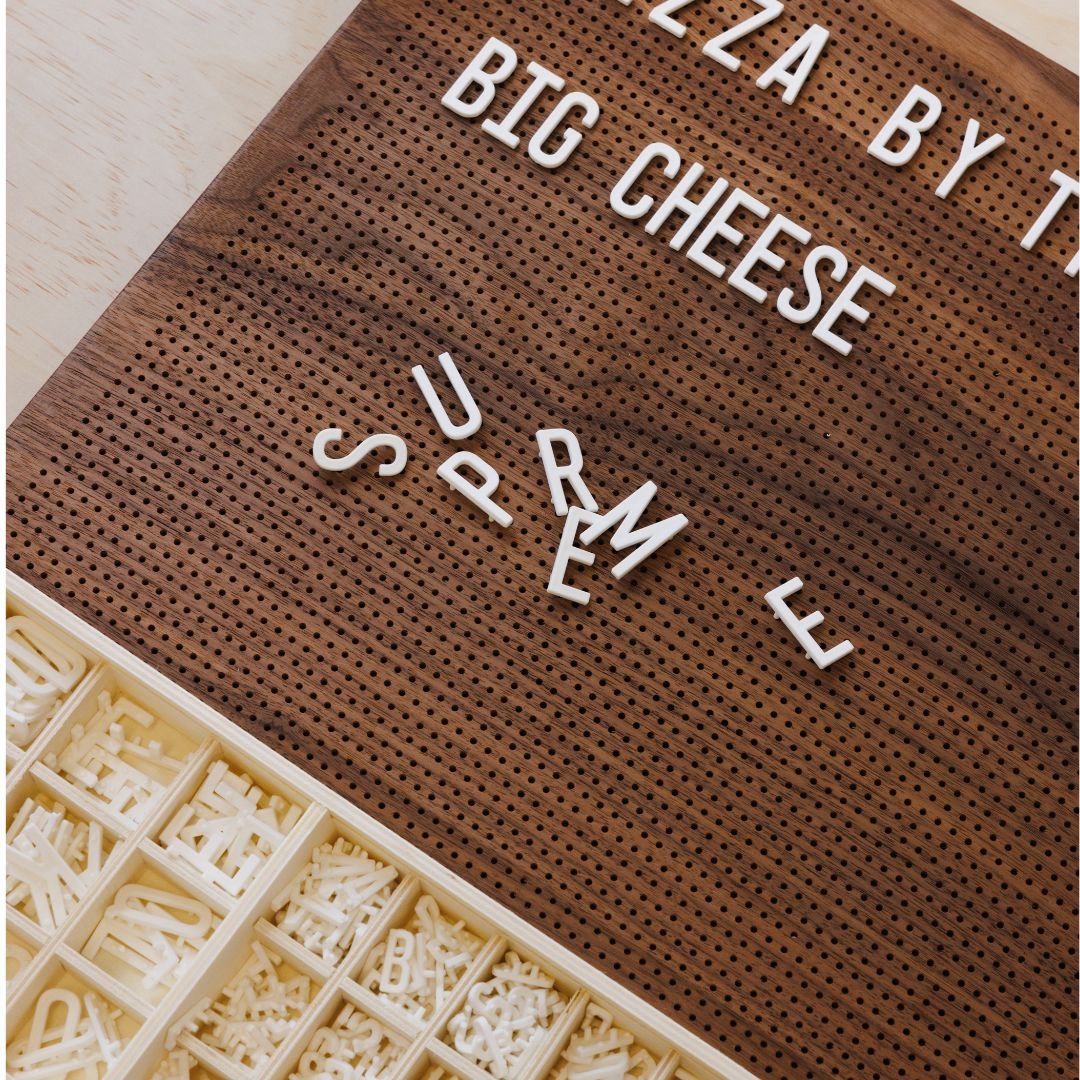

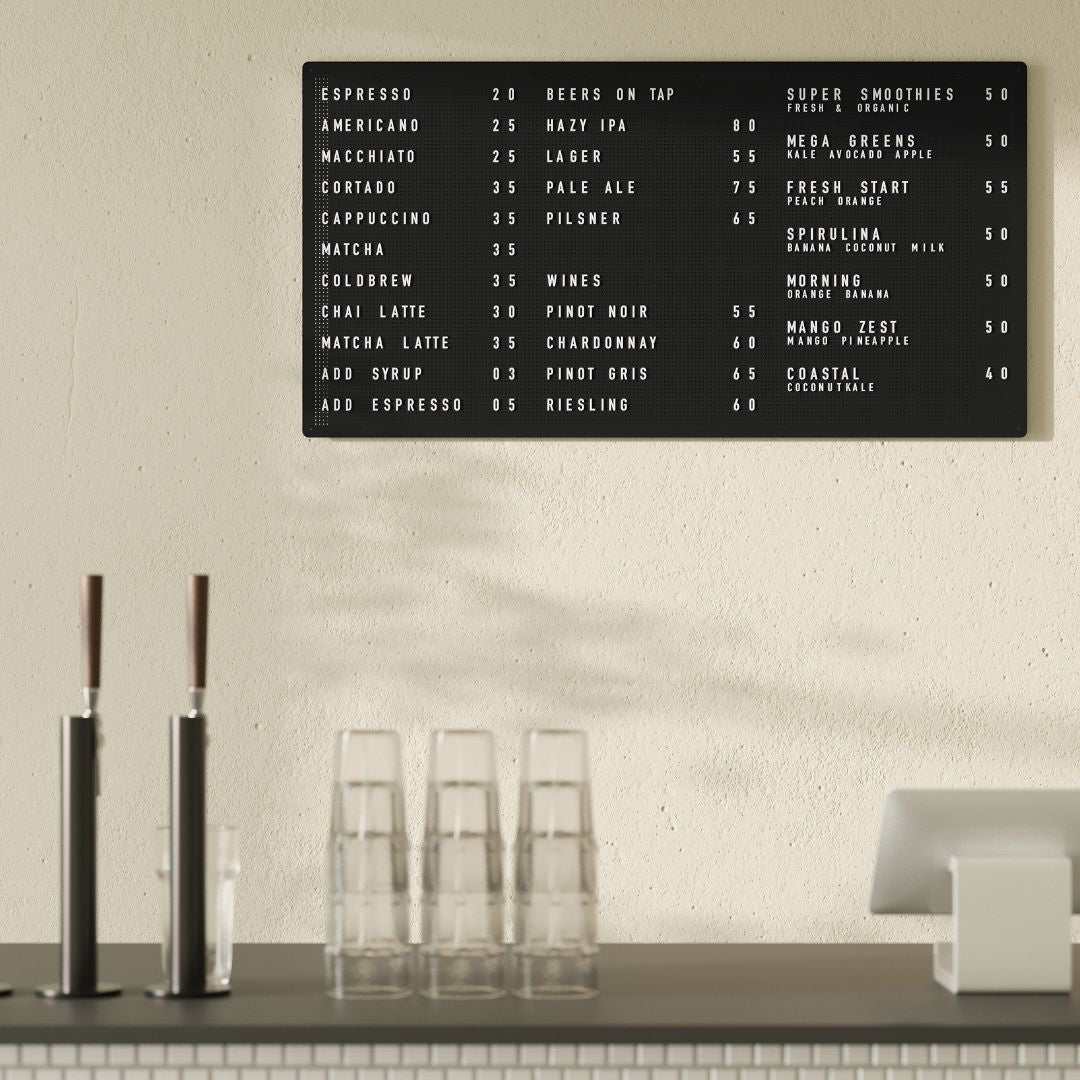

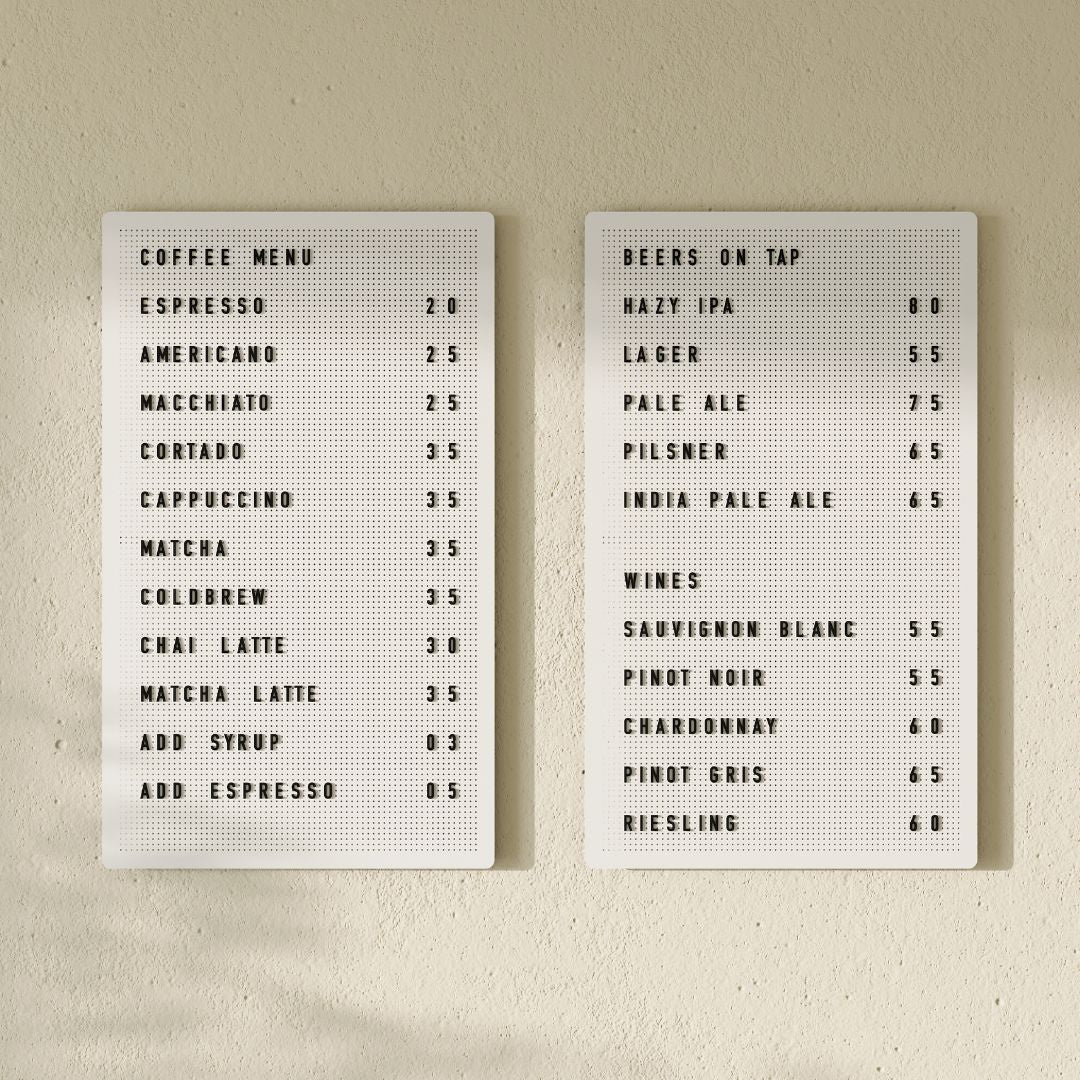

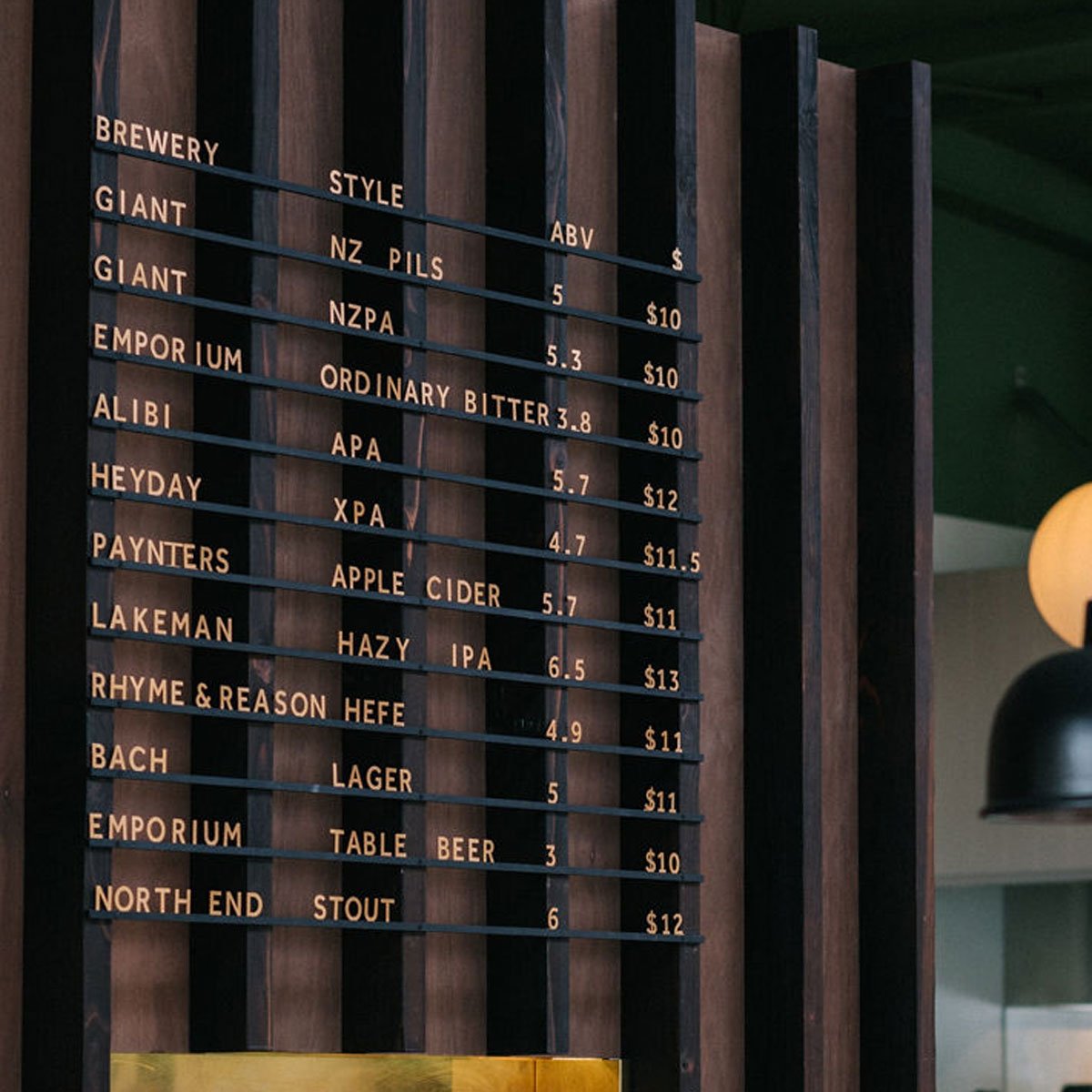

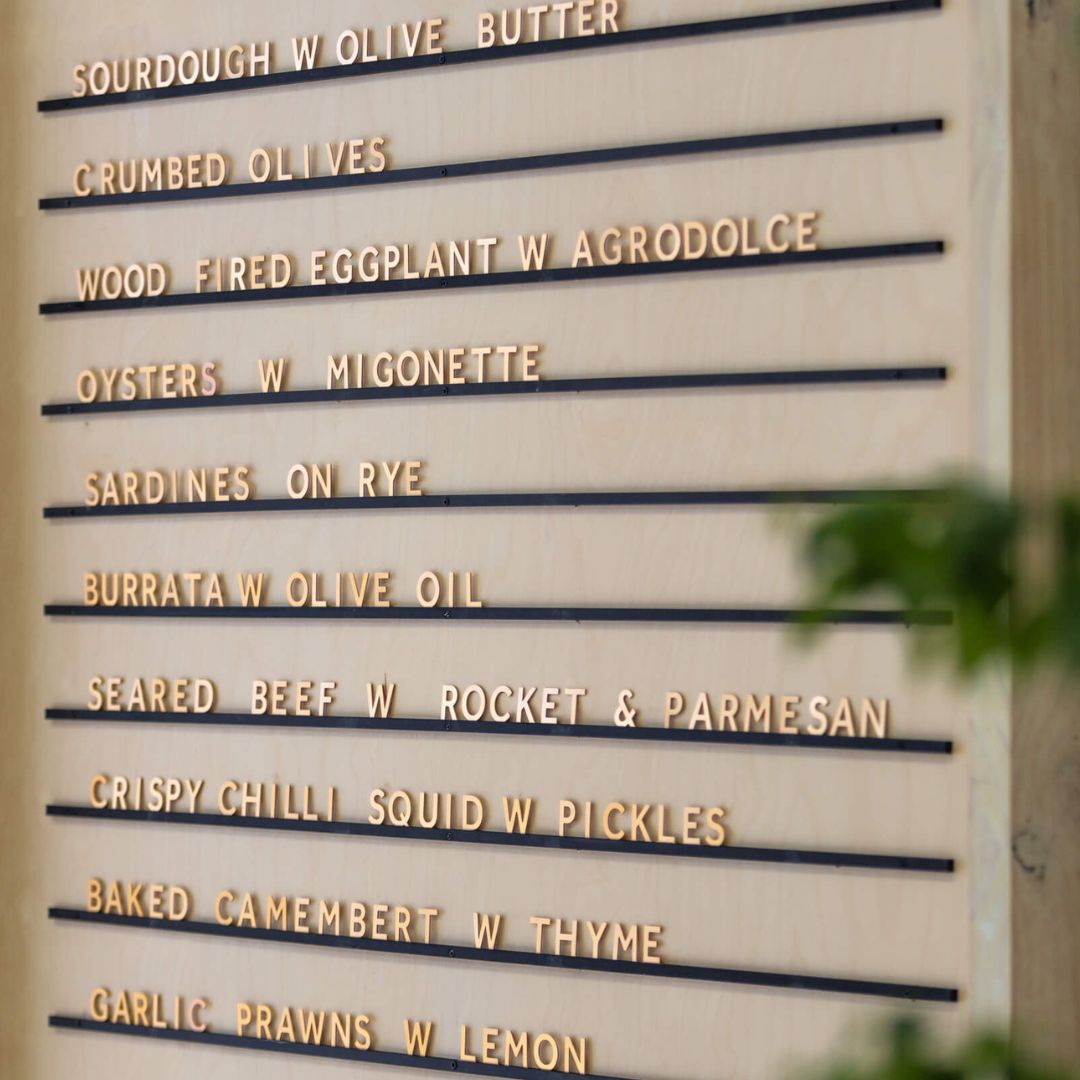

Changeable and Modular Sign Systems

For businesses with evolving menus or frequent specials, flexible signage is a must. Changeable systems like the Magnetic Letter Menu Board, peg boards, or tile displays such as our rail menus let you update information in seconds without the cost of reprinting. This agility is powerful, especially since 59% of diners say they are more likely to order an item labeled as a seasonal special. These systems keep your offerings fresh and exciting for every visitor.

A Note on Digital and Illuminated Signage

While physical signs are timeless, digital signage offers dynamic content that can be updated instantly to reflect new promotions or inventory. Illuminated signs are essential for visibility after dark. Options range from external fixtures like gooseneck lamps to internal LEDs that create a “halo” effect behind letters or light up a whole sign box.

Navigating Practical & Legal Requirements

Before installing a sign, it’s crucial to understand the rules. Overlooking regulations can lead to fines or being forced to remove your sign.

Local Permitting, Zoning, and Codes

Most permanent outdoor signs require a permit from your local city or county government. Zoning laws dictate the size, height, and placement of signs in different areas. For example, a freestanding pylon sign might be allowed in a commercial district but not in a historic one. Always check with your local planning department before commissioning a sign.

Sidewalk Sign Regulations

Even temporary signs like A frames are often regulated. Municipalities typically have rules about size, placement, and hours of display to ensure pedestrian safety. Common rules include maintaining a clear path for pedestrians and bringing the sign indoors when your business is closed.

ADA Accessibility and Compliance

The Americans with Disabilities Act (ADA) has specific requirements for certain types of signs to ensure they are accessible to everyone. This typically applies to signs that identify permanent rooms (like restrooms or exits), as well as directional and informational signs. Key requirements often include:

- High Contrast: Text must stand out clearly from the background.

- Non Glare Finish: The sign should be easy to read under various lighting conditions.

- Tactile and Braille Text: Signs for permanent rooms must have raised letters and corresponding Grade 2 Braille.

- Mounting Height and Location: Signs must be mounted at a specific height (typically between 48 and 60 inches from the floor) and on the latch side of the door.

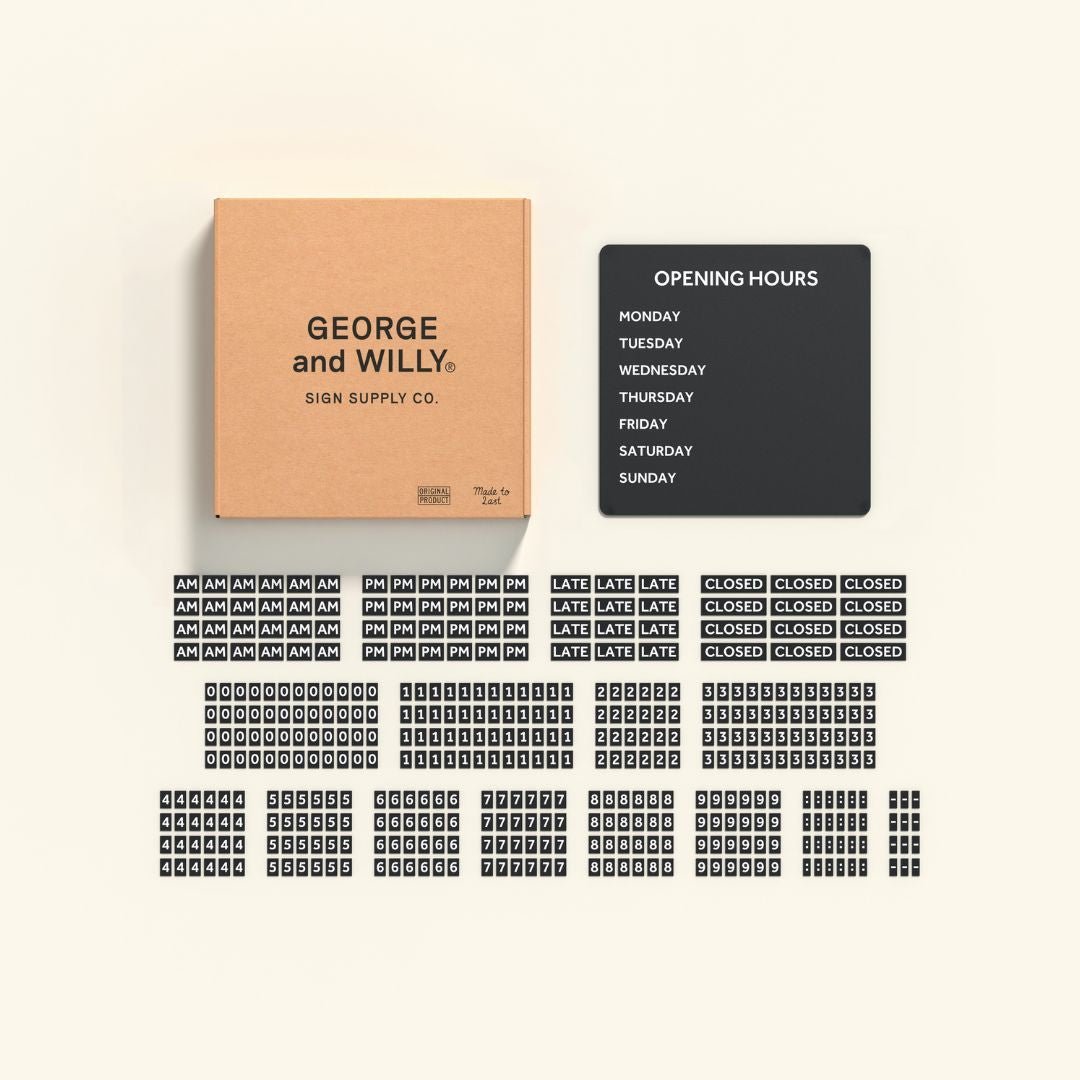

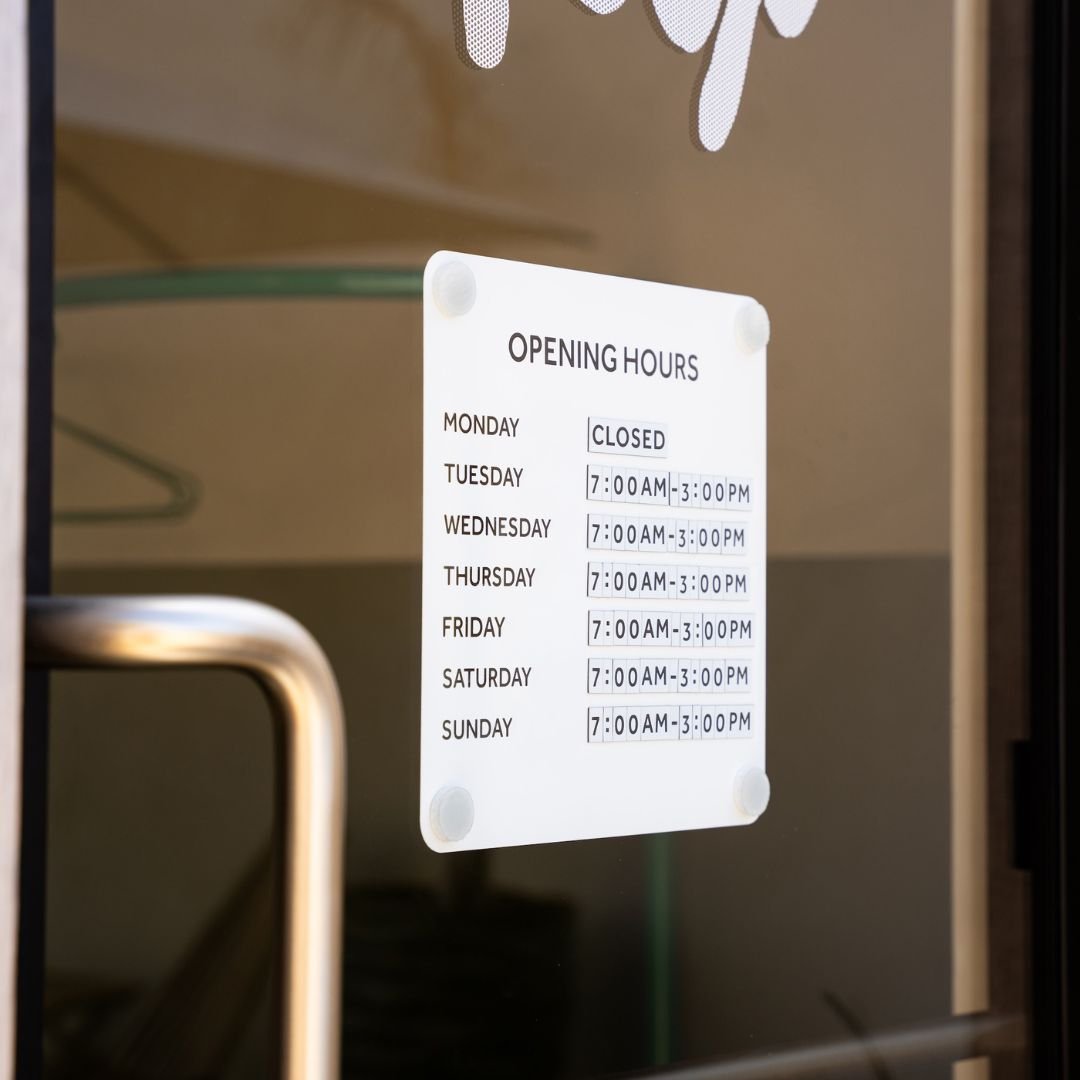

Custom Fabrication vs. Ready Made Signage

When it comes to manufacturing signs, business owners often weigh the options of fully custom work versus high quality, ready made solutions.

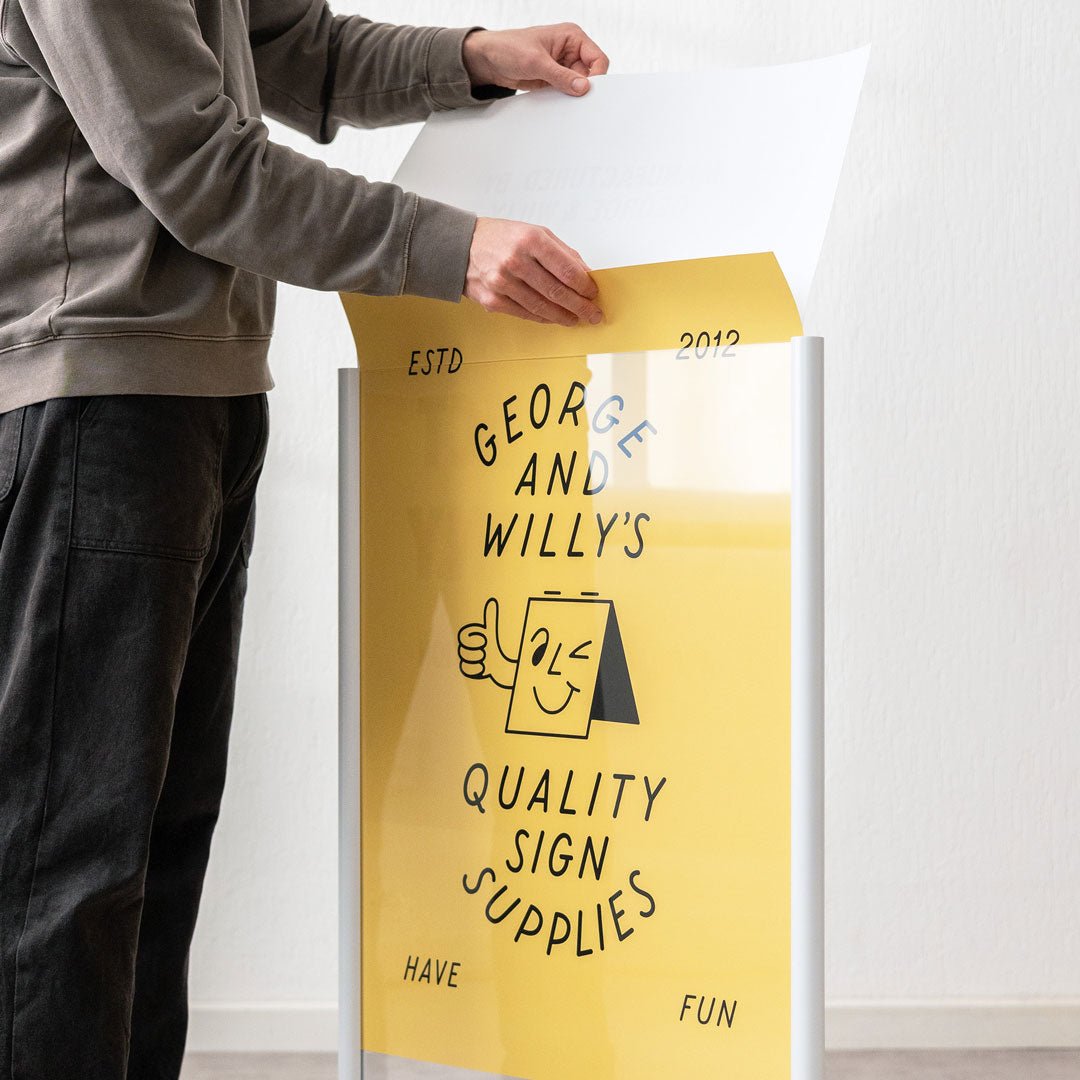

Custom fabrication allows for a completely unique sign but can involve long lead times, high costs, and complex coordination. On the other hand, a growing number of businesses are turning to design led, ready made signage. These pieces, like the thoughtfully designed collection from George & Willy, offer a minimalist, premium aesthetic that fits seamlessly into many brand identities. They are crafted in batches using high quality materials and arrive blank, allowing you to partner with a local signwriter to add your own branding with vinyl decals. This approach gives you a custom look without the typical custom manufacturing timeline or price tag.

Why Quality in Manufacturing Signs Matters

A cheap, flimsy sign can do more harm than good. Quality craftsmanship signals that you care about your business and your customers’ experience.

Readability and Visibility

If a customer can’t read your sign, it might as well not be there. Shockingly, around 50% of consumers report having missed a business entirely because its sign was too small or unclear. Prioritize legible, bold fonts and strong color contrast. Avoid overly decorative scripts or crowding the sign with too much text.

Durability and Brand Perception

Your sign is a reflection of your business. A faded, peeling, or rusty sign can make customers question the quality of your products or services. In fact, nearly 8 in 10 consumers say a sign’s appearance influences their perception of the business itself. Investing in the proper manufacturing signs using durable, weather resistant materials ensures your business always puts its best foot forward.

Maintenance and Cleaning

To protect your investment, regular maintenance is key. Clean your signs periodically with a mild detergent and a soft cloth to prevent the buildup of dirt and grime. For outdoor signs, check mounting hardware to ensure it’s secure, especially after heavy winds or storms. Simple, routine care will keep your signage looking professional for years.

The ROI of Refreshing Your Signage

Signage isn’t a “set it and forget it” item. Styles evolve, and even the best signs can look dated over time. Regularly refreshing your signage can provide a significant return. One of the simplest ways to measure return on investment (ROI) is to track key metrics before and after a change. You can monitor foot traffic, track sales figures, or even conduct customer surveys to see if new signage is having an impact. Studies show that simply adding or updating a sign can increase sales by an average of 10%. It signals that your business is vibrant, current, and paying attention to the details that matter.

Frequently Asked Questions about Manufacturing Signs

What are the most durable materials for outdoor signs?

Powder coated aluminum and stainless steel are excellent choices for outdoor signs. They are rust resistant, waterproof, and built to withstand sun, wind, and rain for many years, making them a wise investment in the manufacturing signs process.

How much does business signage cost?

Costs vary widely based on size, material, and whether it is a custom or ready made product. A simple A frame sign might cost a few hundred dollars, while a large, illuminated custom sign could be several thousand. Ready made systems often provide a cost effective way to achieve a high end look.

What is the difference between a blade sign and an A frame sign?

A blade sign is typically a small, double sided sign that projects perpendicularly from a building’s facade, making it visible to pedestrians walking down the street. An A frame sign, or sidewalk sign, is a portable, foldable sign that stands on the ground directly in front of a business to capture the attention of passersby.

How often should I update my business signs?

A good rule of thumb is to evaluate your main exterior sign every 5 to 7 years. Interior signs that feature pricing or promotions may need updating much more frequently. If your sign looks faded, damaged, or no longer reflects your current branding, it’s time for a refresh.

Can I customize a ready made sign?

Absolutely. Most high quality ready made signs are designed as a blank canvas. You can easily work with a local signwriter to apply your logo and branding using vinyl decals. This gives you the speed and quality of a ready made product with the unique identity of a custom piece. For powder coated metal surfaces, using a high tack vinyl is recommended to ensure strong adhesion.