Choosing outdoor sign materials is the difference between a sign that fades fast and one that greets customers for years. The right material resists rain, sun, wind, and busy sidewalks, all while matching your brand feel. If you run a café, retail store, or studio, materials shape first impressions before anyone steps inside.

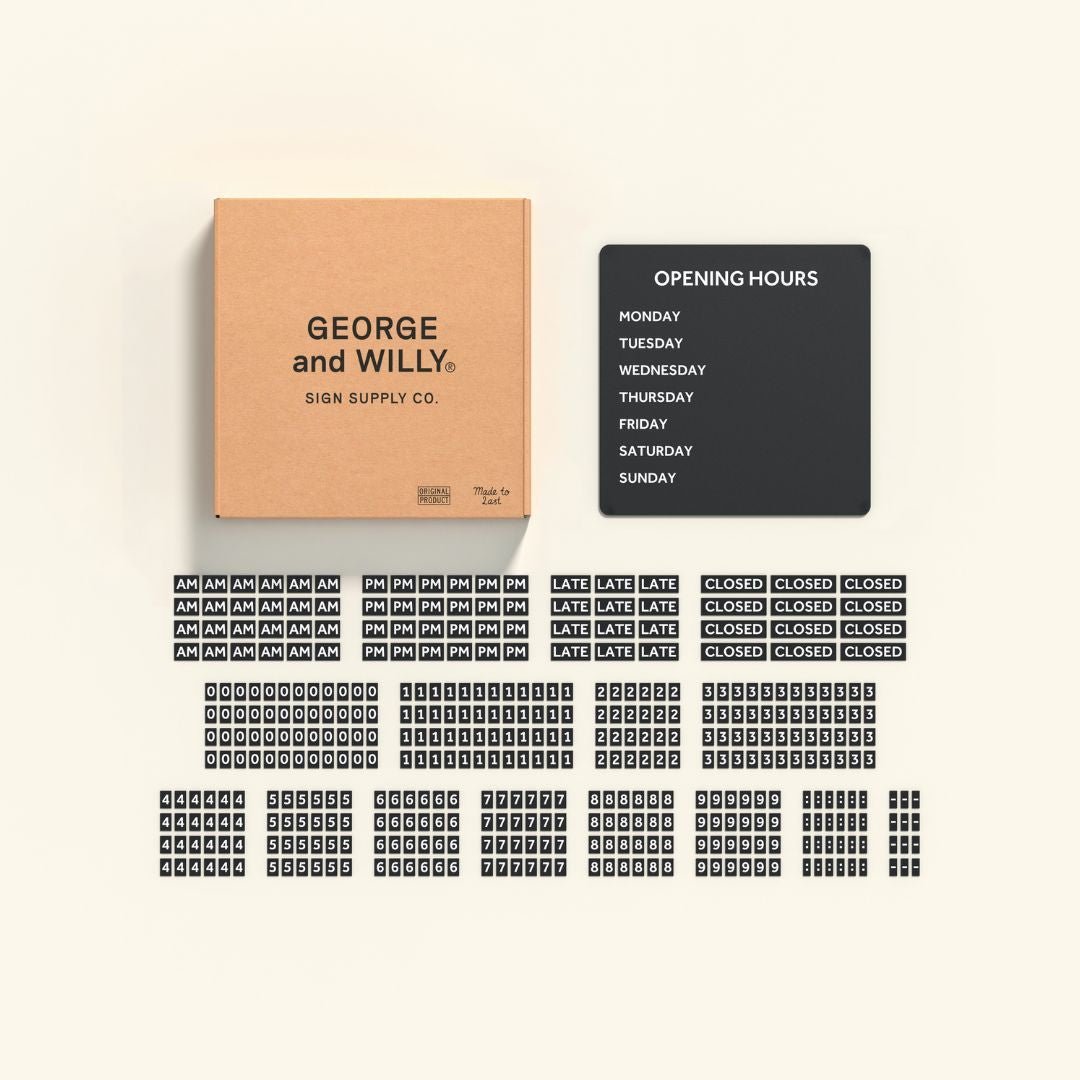

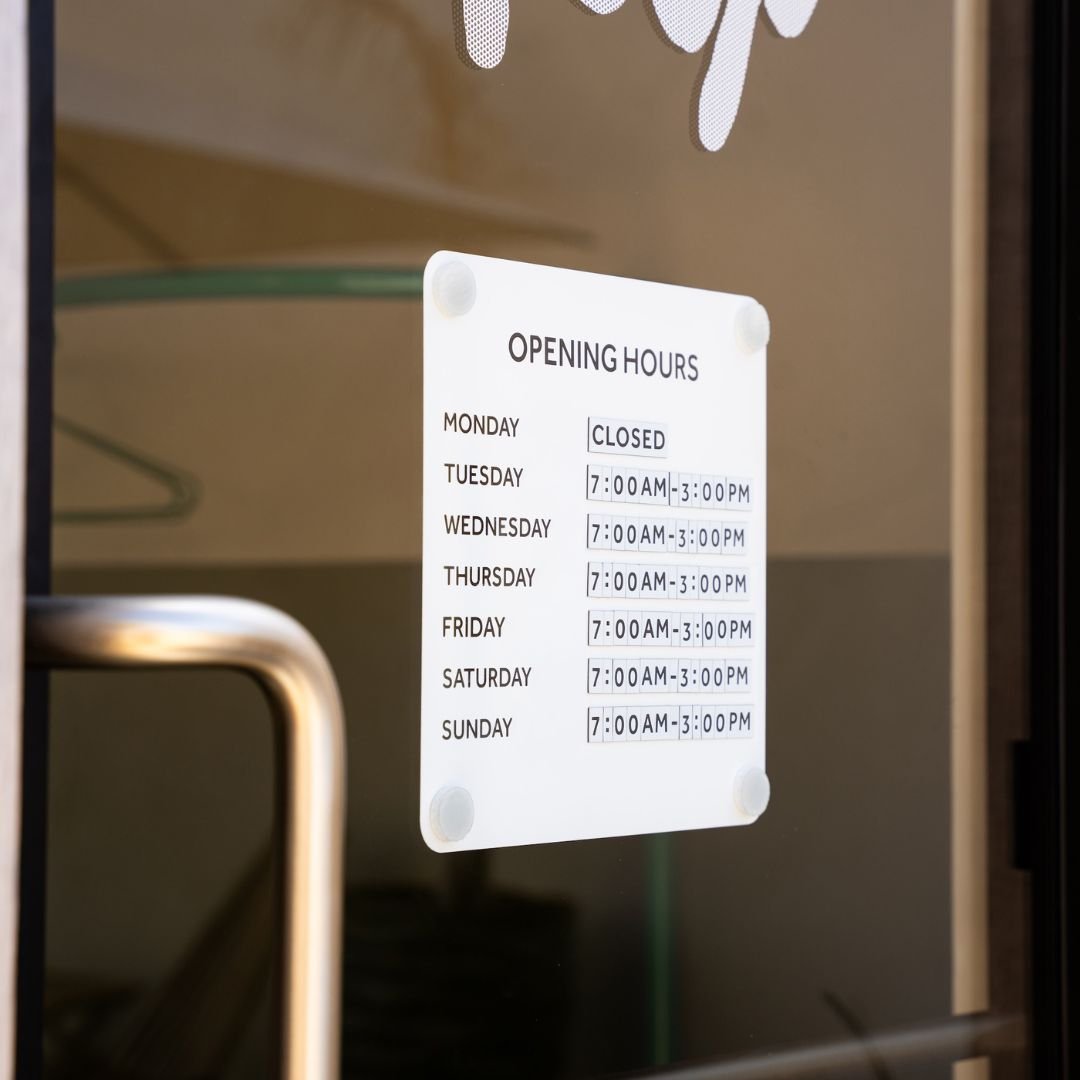

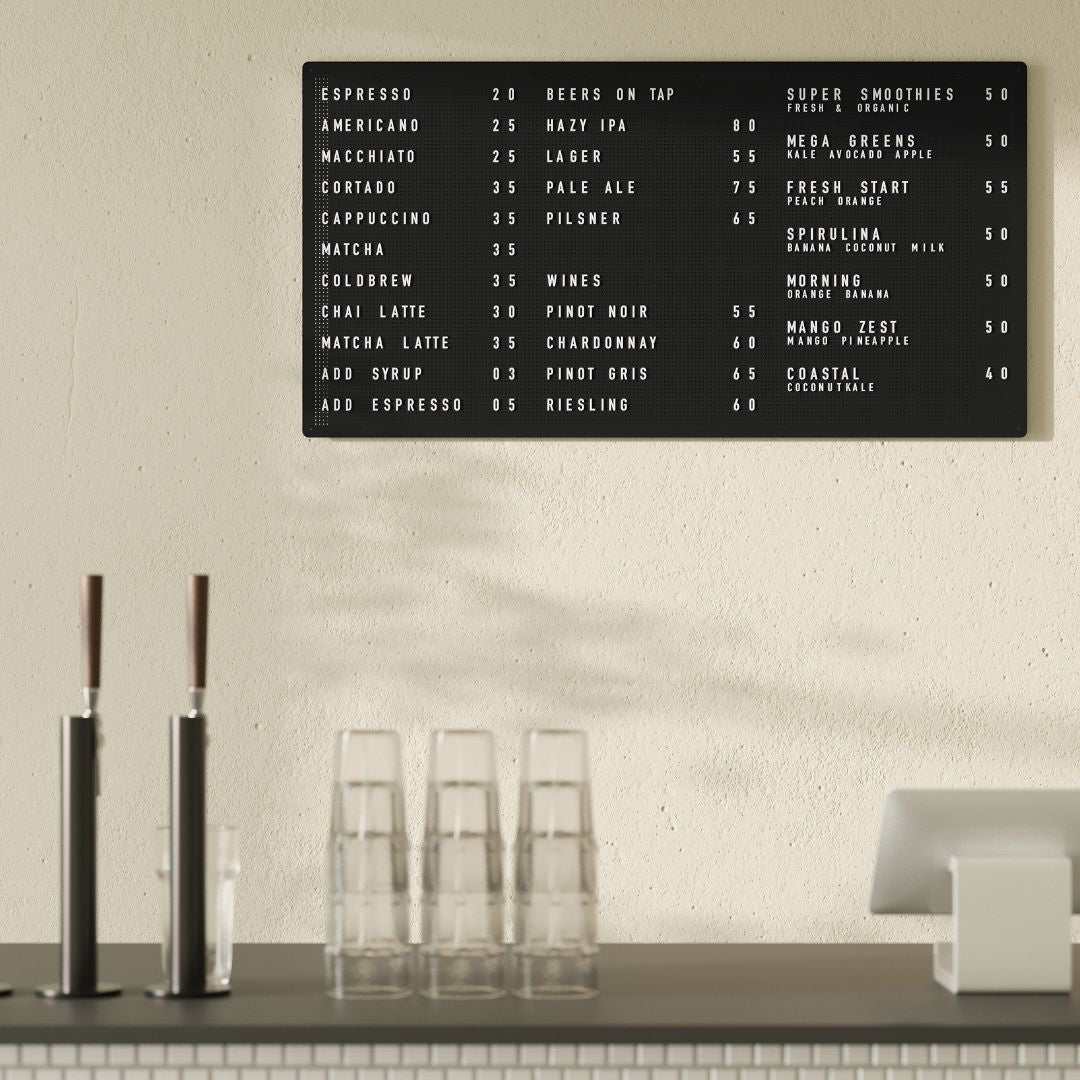

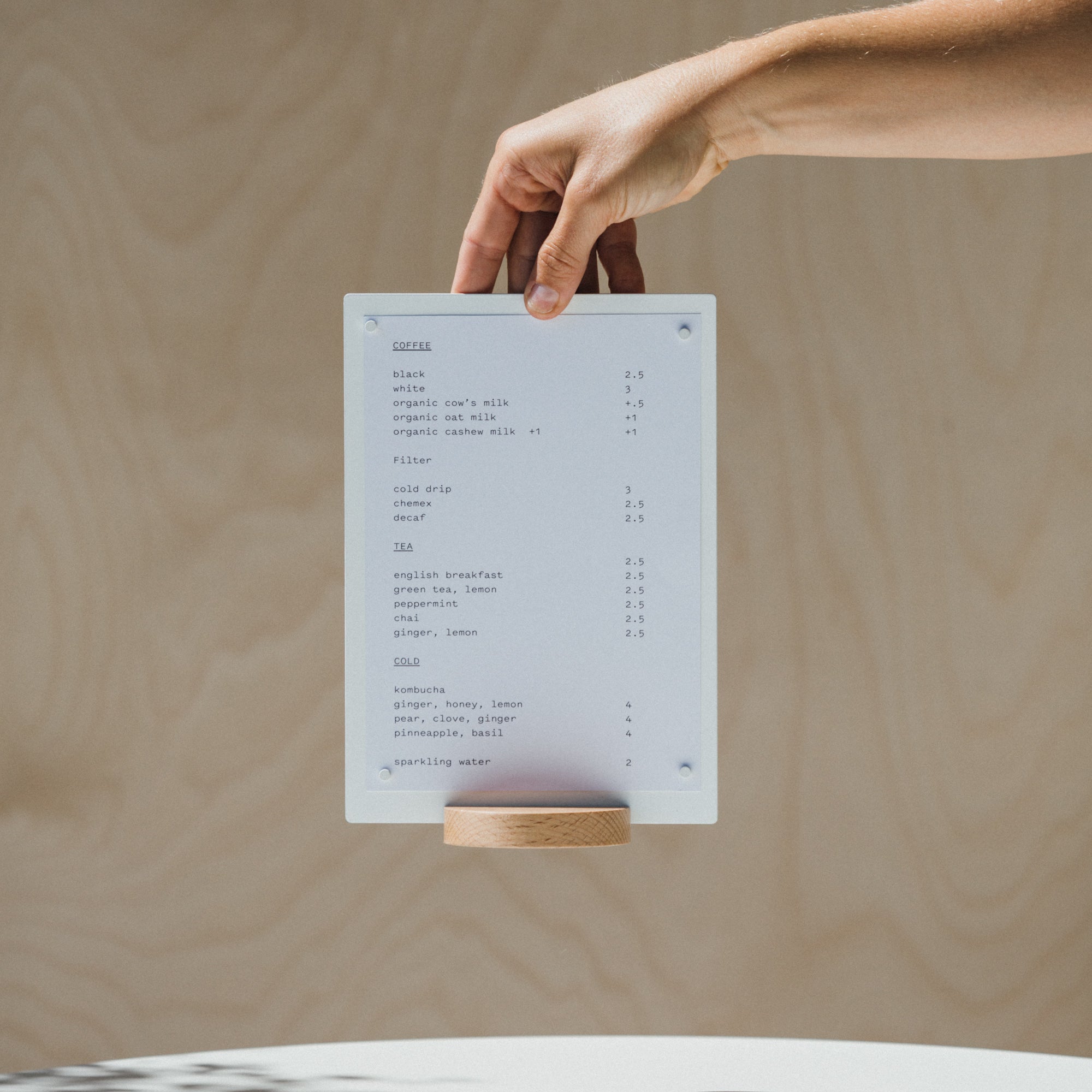

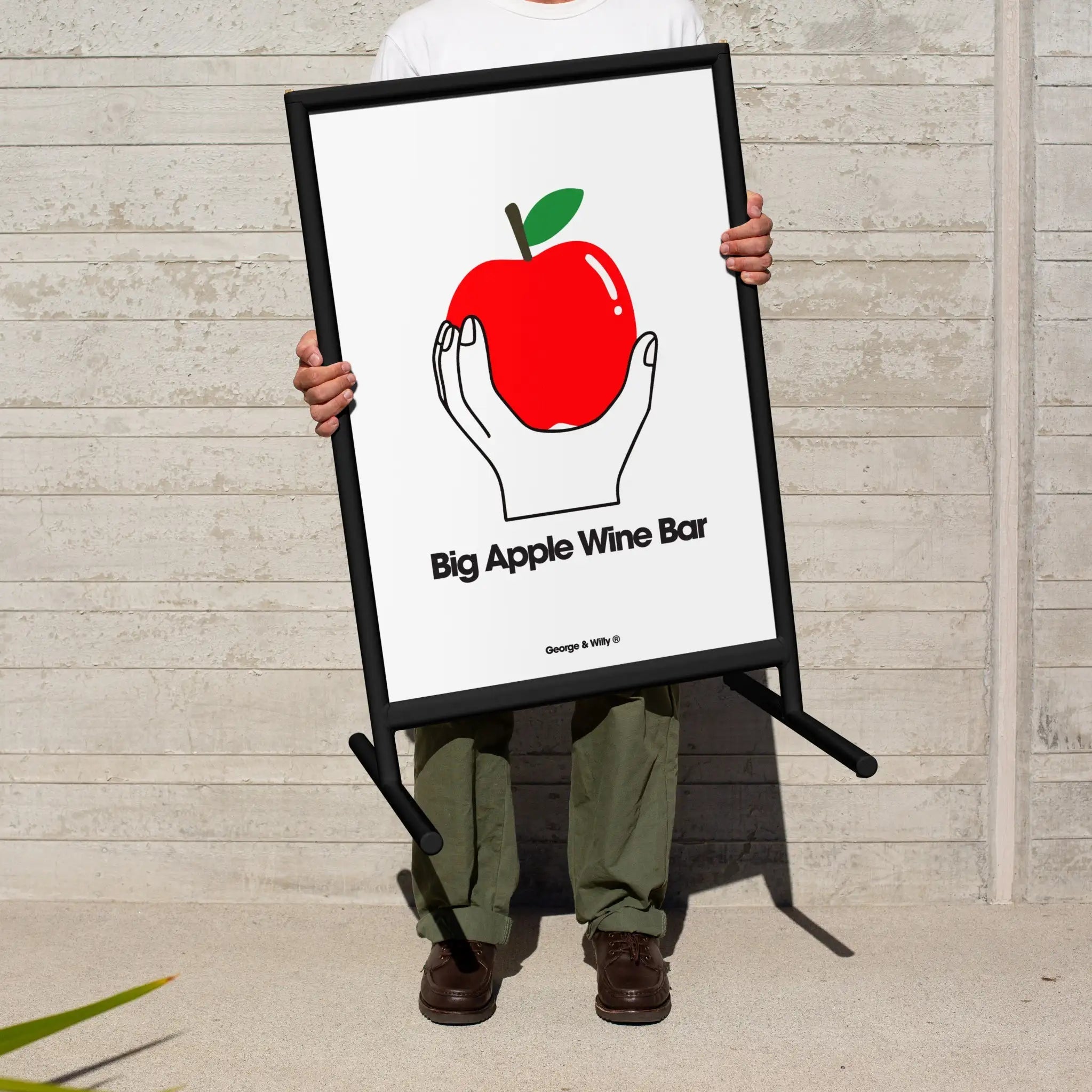

At George & Willy, many storefront signs are made from powder coated aluminum or steel for reliable weather resistance, and changeable menu systems use magnetic letters or tiles that keep updates quick. This guide breaks down how to evaluate outdoor sign materials, match them to sign types, and plan a budget that considers lifespan and maintenance. If you are ready to explore ready made options, browse George & Willy.

Key selection criteria for outdoor sign materials

Material choice is part performance and part presentation. Use these criteria to shortlist outdoor sign materials for your space.

Climate and exposure. Rain, coastal air, snow, and full sun all influence performance. Powder coated aluminum resists rust in wet or salty environments, while timber needs the right finish and care.

Weight and wind. Heavier metals can be stable in gusts, yet smart design and mounting matter more. Look for balanced frames, proper fixings, and consider a Sandbag for A-Frame Signs for extra stability in exposed sites.

Finish quality. Powder coating adds a durable finish that resists chipping better than many paints when handled correctly. Smooth finishes read cleaner at a distance.

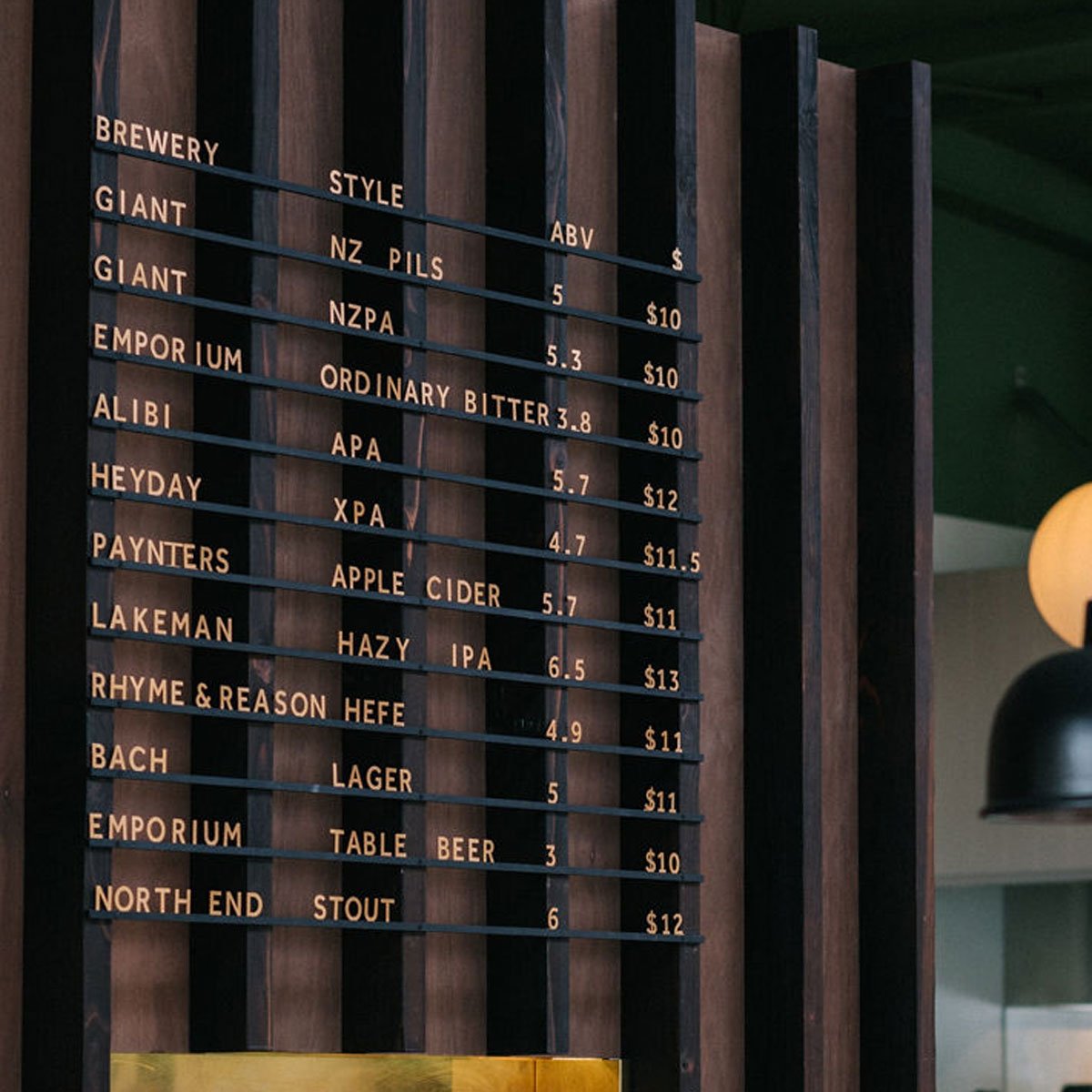

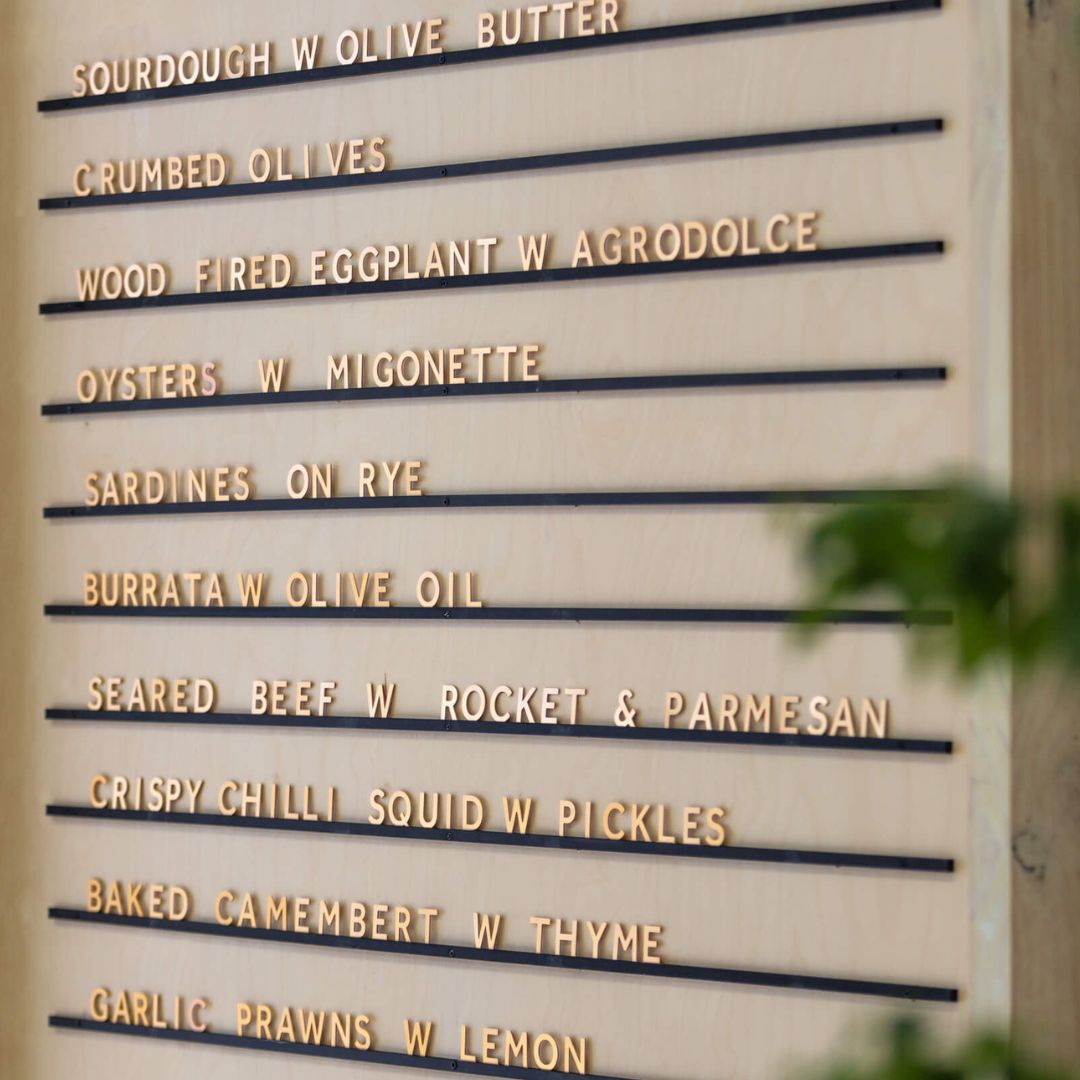

Update frequency. If you change menus or promos often, choose systems with magnetic letters, peg tiles, or a cafe menu display, not printed sheets.

Lighting. Backlit or outdoor light box signs need UV stable faces and sealed housings. Exterior rated LEDs and gaskets matter for the long haul.

Hardware and installation. Complete kits with mounting hardware and clear instructions reduce install time and mistakes.

Warranty and support. A two year warranty on workmanship and materials provides confidence for outdoor use.

Logistics and lead time. If your opening date is near, prioritize materials and brands with reliable stock and fast shipping.

Outdoor sign materials that check most of these boxes will save time and money while improving customer visibility.

Match outdoor sign materials to use cases and sign types

Picking a material gets easier when you map it to how and where the sign will live.

Sidewalk and A frame signs

Best materials. Powder coated aluminum or steel for frames, with removable panels for decals. These materials are durable, clean looking, and manageable in weight.

Why it works. They handle daily setup and pack down, plus occasional bumps on busy streets. George & Willy’s A-Frame Sign weighs about 8.8 lb and includes both brass and color matched straps, which makes handling simple while keeping a premium look. See options at George & Willy.

Blade and projecting signs

Best materials. Aluminum or steel panels with powder coating, stainless hardware, and sealed fixings, available in round profiles like the wall mounted hanging signs.

Why it works. Mounted at height and exposed to wind, these signs benefit from rigid metals and solid brackets that resist flex and corrosion. See examples like the wall blade signs.

Light box and illuminated signs

Best materials. Aluminum bodies with outdoor rated LEDs, acrylic or polycarbonate faces, and weather seals.

Why it works. Metals conduct heat away from electronics, and UV stable faces keep graphics legible. George & Willy’s light box signs start around 680 USD and include mounting hardware.

Wall plaques and lettering

Best materials. Aluminum, stainless steel, or sealed timber for accent warmth. Choose films or vinyl decals for graphics.

Why it works. Metals give sharp edges and a refined finish, while timber adds character in covered entries with periodic maintenance.

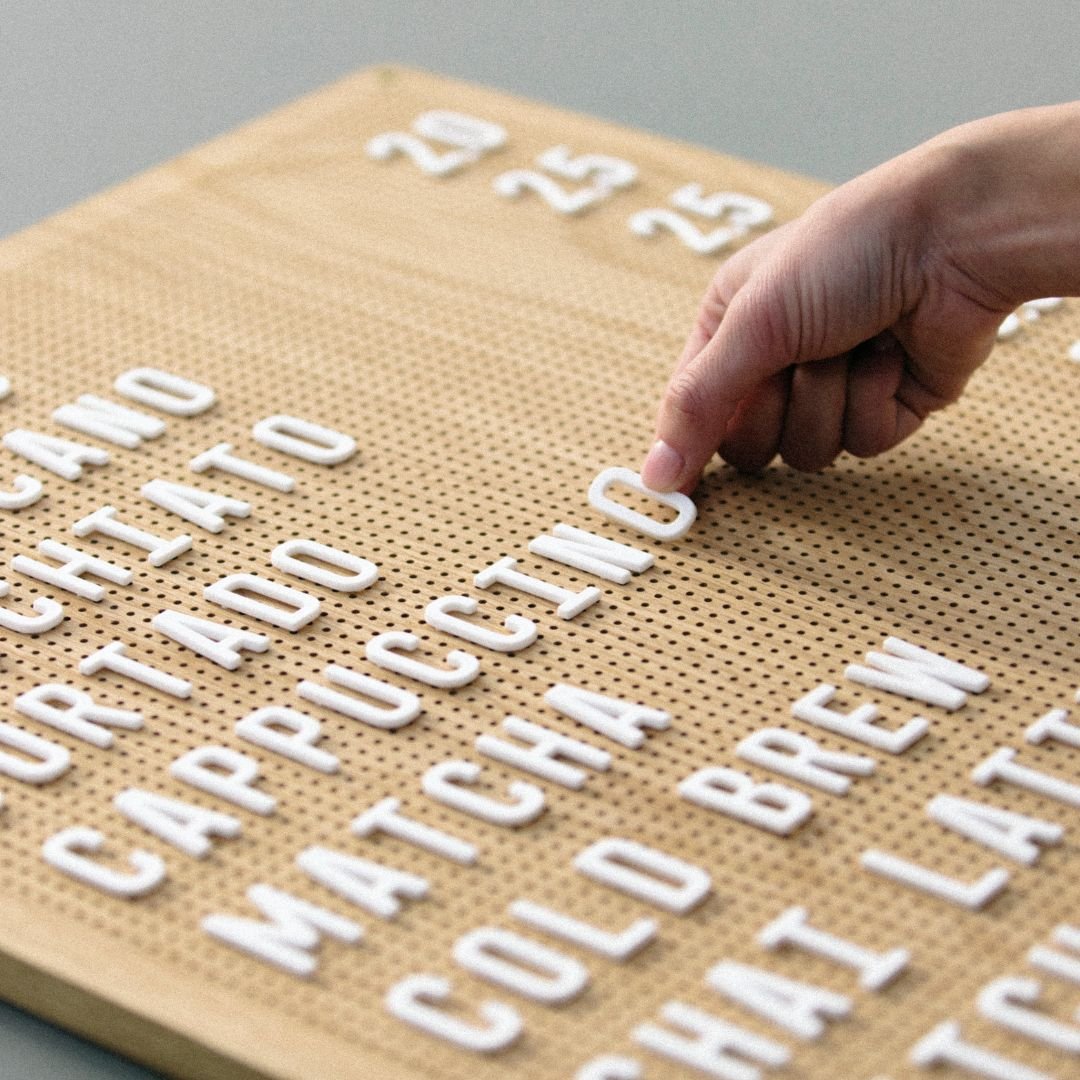

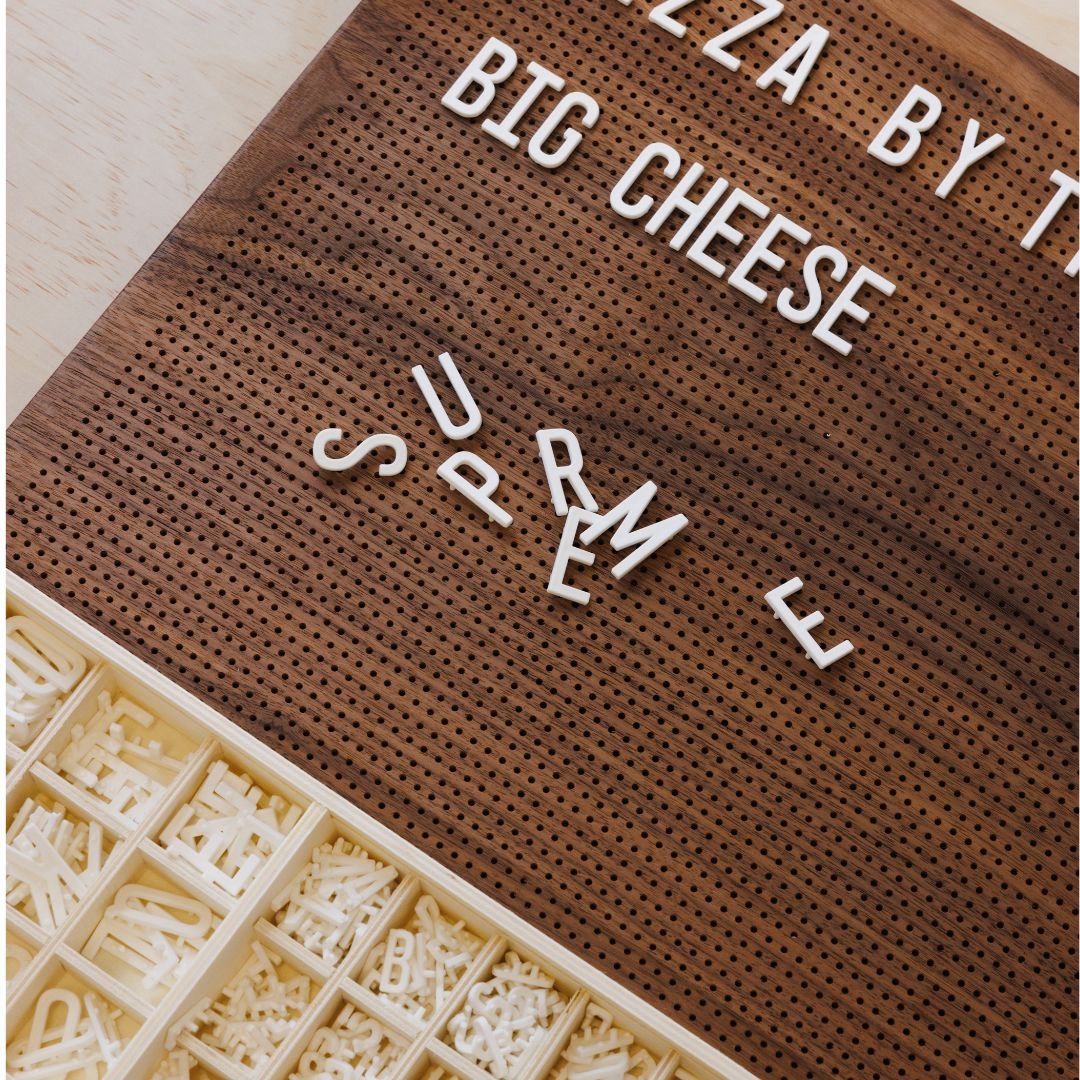

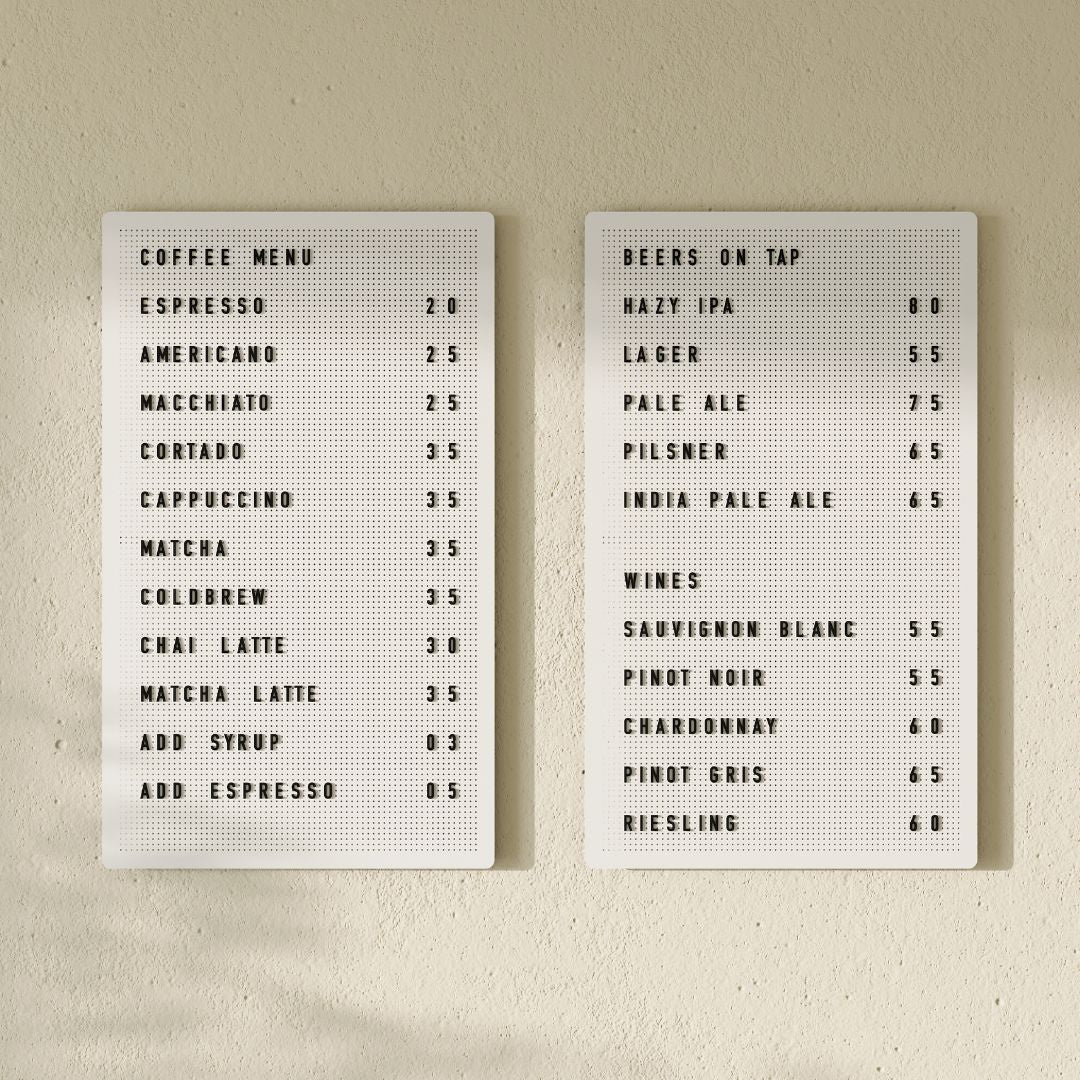

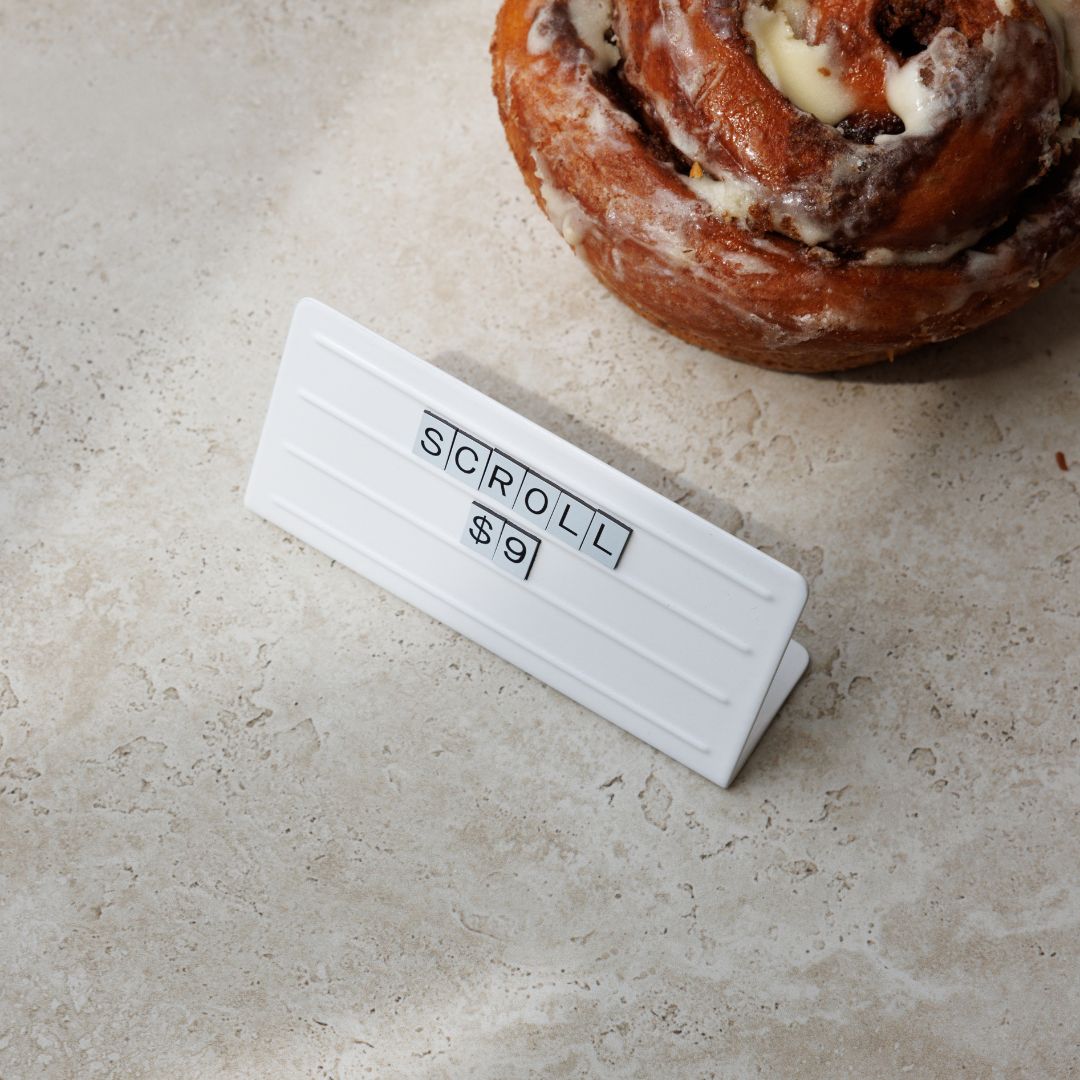

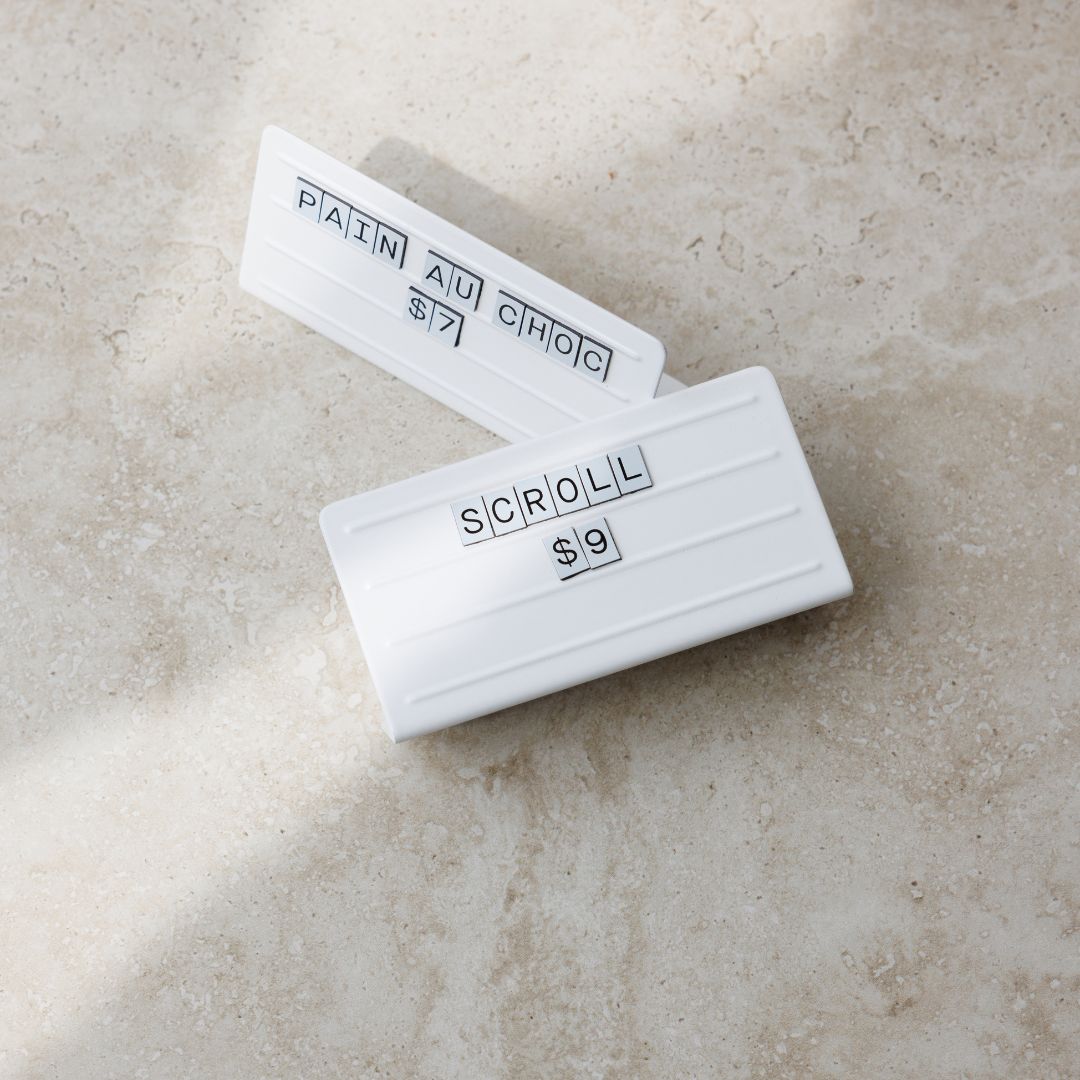

Menu boards and changeable systems near entries

Best materials. Powder coated aluminum and steel rails, magnetic letters, or reversible tiles that tolerate frequent updates.

Why it works. Systems like the Magnetic Menu Board ship with 1,032 characters and ten rails, so teams can reconfigure prices and items quickly without reprints. Explore options at George & Willy.

The goal is simple, match outdoor sign materials to the way customers encounter your space, the local climate, and how often your content changes.

Top 10 Outdoor Sign Materials

With the key factors for outdoor signage in mind, this section spotlights the ten materials professionals reach for when durability, weather resistance, and clean visuals matter most. Grouped together because they’re the most proven, widely available substrates that balance longevity, cost, and printability, these options span metals, composites, plastics, and films to fit virtually any environment. Use the quick notes that follow to match each material to your installation conditions, budget, and desired lifespan.

1. Aluminum Composite Material (ACM)

If there’s a default for modern outdoor panels, it’s ACM: two thin aluminum skins bonded to a rigid core that stays dead‑flat. It looks premium without the premium weight, making storefront fascias and wayfinding feel intentional, not improvised.

Look & typical uses: Matte, satin, or gloss faces in solid colors, metallics, brushed, or print‑ready white; common in 3 mm and 6 mm. Ideal for fascia panels, blade signs, directories, and post‑and‑panel.

Weather & upkeep: Coil‑coated faces shrug off UV, rain, and corrosion; the core won’t swell and resists oil‑canning. Expect simple soap‑and‑water cleanings; optional PVDF or anti‑graffiti films ease graffiti removal.

Install & weight: Light yet stiff (3 mm ≈ 0.75 to 0.80 lb/ft²), cuts and routes cleanly. Mount with screws, Z‑clips, standoffs, or VHB; great for A‑frames. Perfect base for printed or cut vinyl from local signwriters.

Cost & lifespan value: Medium cost (more than corrugated plastics, less than solid aluminum or steel) with 10 to 15+ years outdoors. Low freight and quick installs keep total cost friendly for multi‑site rollouts.

2. Dibond

Think of Dibond as the name‑brand version of ACM: ultra‑flat, beautifully finished, and consistent from batch to batch. For brand teams, that consistency keeps multi‑location storefronts looking identical.

Look & typical uses: Pre‑painted aluminum skins over a PE core in matte, gloss, colors, brushed aluminum, and mirror. Frequently used for storefront fascia, tenant panels, and menu boards.

Weather & upkeep: UV‑resistant coil coats, corrosion‑proof faces, and a composite core that rides out temperature swings without warping. Upkeep is minimal, with mild detergent wipe‑downs; no sealing required.

Install & weight: Light but rigid (around 1 lb/ft² at 3 mm), routes crisply for clean edges. Installs with screws, standoffs, Z‑clips, or VHB tape; accepts vinyl overlays and digital prints.

Cost & lifespan value: Mid‑tier price with 7 to 10+ years of outdoor life. Lower freight, fast installs, and easy re‑facing of graphics keep lifecycle costs predictable.

3. Aluminum

The classic street‑sign material: solid aluminum sheet that endures for years, even when the weather doesn’t. It’s the go‑to for parking, traffic, and any sign that must last without complaint.

Look & typical uses: Smooth, paintable face in mill finish, painted white, or brushed; common gauges 1.6 to 3 mm (0.063 to 0.125 in). Perfect for regulatory signs, long‑term plaques, and rugged wall plates.

Weather & upkeep: Naturally corrosion‑resistant and unfazed by UV, rain, or temperature swings. Occasional mild‑soap clean keeps it fresh; UV laminate or baked enamel slows graphic fade.

Install & weight: Heavier than ACM but still manageable; drills, shears, and bends well. Mount with screws, rivets, or brackets; stable base for reflective sheeting and cut vinyl.

Cost & lifespan value: Medium‑to‑high material cost, but 10 to 20+ years outdoors is common. A smart pick when “buy once” beats “replace often,” especially for high‑exposure locations.

4. Alumalite

Alumalite pairs painted aluminum skins with a fluted polypropylene core, landing a sweet spot of rigidity, durability, and weight. It’s a favorite for post‑and‑panel IDs and drive‑thru messaging.

Look & typical uses: Smooth baked‑enamel look in matte or gloss, often double‑sided at 6 mm. Great for storefront IDs, campus wayfinding, and freestanding panels.

Weather & upkeep: Aluminum faces resist corrosion; the poly core won’t swell in wet conditions. UV‑stable coatings manage sun and rain; quick wipe‑downs and optional overlaminate keep graphics sharp.

Install & weight: Noticeably lighter than solid aluminum or MDO, making large panels easy to handle. Installs with screws, rivets, or VHB; compatible with vinyl decals and prints.

Cost & lifespan value: Solid mid‑tier choice with 7 to 10 years outdoors. Lower freight and simple installation trim project budgets without sacrificing presence.

5. Self Adhesive Vinyl

When you need branding everywhere (on windows, doors, and panels), self‑adhesive vinyl is the flexible backbone. Cut lettering, full‑color prints, even frosted effects all travel well across a rollout.

Look & typical uses: Calendered (budget) and cast (premium) films in matte, gloss, satin, clear, reflective, frosted, and perforated options. Ideal for window promos, panel graphics, and decals.

Weather & upkeep: Outdoor‑rated adhesives and films handle UV, moisture, and temperature swings; lamination boosts durability. Maintenance is light: mild‑soap wipe‑downs; edge sealing helps in high‑clean zones.

Install & weight: Ultra‑thin (2 to 4 mils) and easy to squeegee; air‑egress liners speed installs. Works on glass, metal, and plastics; readily cut or print‑and‑cut by local signwriters.

Cost & lifespan value: Low‑to‑medium cost. Expect 3 to 5 years for quality calendered, 5 to 8 (sometimes more) for cast with laminate. Fast shipping and local application keep rollout costs lean.

6. Colourbond

Pre‑finished, coil‑coated steel, often known as Colorbond, brings a crisp, architectural look with serious toughness. It’s a stalwart for fascias where uniform color and long service matter.

Look & typical uses: Baked‑on finishes in matte, low‑sheen, or gloss on galvanized or aluminum‑zinc steel, typically 0.48 to 0.70 mm. Used for shopfront fascias, canopy cladding, and menu backers.

Weather & upkeep: Factory coatings (polyester, SMP, PVDF) offer strong UV, moisture, and impact resistance; protect cut edges to prevent rust. Maintain with rinses and gentle detergent; touch up nicks promptly.

Install & weight: Heavier than plastics and ACM (roughly 3.8 to 5.5 kg/m² at common gauges) yet manageable. Fix to timber, steel, or masonry; best as fixed panels; takes vinyl cleanly.

Cost & lifespan value: Mid‑tier pricing with 10 to 20 years outdoors in typical environments. Minimal cleaning and color stability offset occasional edge‑care costs across a portfolio of sites.

7. Corflute

For fast, lightweight, and budget‑friendly signs, Corflute (aka Coroplast/Correx) is the seasonal hero. It makes pop‑up promotions and event wayfinding effortless to deploy and replace.

Look & typical uses: Corrugated polypropylene in matte to semi‑gloss, 3 to 10 mm, usually white or black. Ideal for curbside signs, temporary menus, real‑estate, and campaign wayfinding.

Weather & upkeep: Waterproof and non‑corroding with decent impact resistance; prolonged sun can fade and embrittle; specify UV‑stabilized sheets or add laminate. Simple wipe‑downs; avoid harsh solvents and extreme heat.

Install & weight: Ultralight and easy to cut. Slides into A‑frames, mounts with H‑stakes, zip‑ties, or screws. Use high‑tack vinyl or primers for best adhesion.

Cost & lifespan value: Low cost with a 6 to 18 month typical life (up to 2 to 3 years in mild climates with UV‑stable materials). Perfect for seasonal multi‑site rollouts where agility beats permanence.

8. Acrylic

Crystal‑clear and UV‑stable, acrylic delivers that glass‑like look without the weight. From lightbox faces to dimensional letters, it reads clean and premium on the street.

Look & typical uses: Cast or extruded PMMA in clear, opal, translucent colors, and opaques with matte or gloss. Common in illuminated cabinets, menu cases, and channel letter faces.

Weather & upkeep: Resists UV and moisture, won’t corrode, but is less impact‑tough than polycarbonate. Clean with mild soap and water only; avoid solvents and abrasives to prevent crazing.

Install & weight: About half the weight of glass; cuts, routes, and bonds well. Mount in frames or with standoffs/VHB; allow for thermal expansion. Takes printed and cut vinyl nicely.

Cost & lifespan value: Medium cost with 5 to 10+ years outdoors when well supported. Easy handling reduces install labor; choose polycarbonate instead if vandal resistance is critical.

9. Vinyl

Here, think banner vinyl: flexible PVC scrim that turns into durable outdoor banners, fence wraps, and temporary storefront covers. It’s the fast, big‑canvas solution for announcements and openings.

Look & typical uses: 13 to 18 oz front‑lit or blockout, matte to low‑gloss, with smooth or lightly textured faces. Great for street‑pole banners, storefront banners, and construction hoardings.

Weather & upkeep: Engineered for UV and moisture; welded hems and reinforced grommets boost wind resilience. Clean with gentle detergent; avoid high‑pressure edges to prevent lifting.

Install & weight: Flexible and rollable; easy to ship and store. Hang with grommets, pole pockets, or track systems; compatible with large‑format print and spot‑color vinyl overlays.

Cost & lifespan value: Low‑to‑medium cost with a 1 to 5 year outdoor window depending on weight, exposure, and finishing. Excellent reach‑per‑dollar for campaigns and grand openings across many sites.

10. Stainless Steel

When permanence and prestige are non‑negotiable, stainless leads. From satin plaques to mirror‑polished letters, it signals quality that outlasts trends and weather.

Look & typical uses: 304 for most urban installs; 316 for coastal/salt. Finishes include brushed satin, mirror polish, bead‑blast matte, and PVD colors. Common for plaques, dimensional letters, and architectural panels.

Weather & upkeep: Outstanding UV, moisture, and temperature resistance; high impact toughness. Use non‑chloride cleaners and occasional passivation; 316 resists tea‑staining near coasts.

Install & weight: Heavier than aluminum; demands robust substrates and hardware. Typical mounts include concealed studs, through‑bolts, or standoffs; accepts cast vinyl and UV‑printed graphics.

Cost & lifespan value: High material and fabrication cost, but 15 to 30+ years outdoors is realistic. Minimal repainting and enduring finish help justify the premium over time.

Cost vs lifespan, planning your budget

Think in total cost of ownership, not just the initial price. Spending slightly more on durable outdoor sign materials usually pays back through fewer replacements and less maintenance.

Expect better lifespan from powder coated aluminum and steel than basic painted sheet metal in wet climates, since powder coating and non ferrous metals resist rust.

Real world price examples to benchmark. A board sign about 420 USD, Rounded Sidewalk Sign about 420 USD, Poster Sidewalk Sign about 490 USD, Large Sidewalk Sign about 680 USD, and Round Light Box Sign from about 680 USD. Prices observed in October 2025 and may change.

Menu systems can consolidate costs. A Magnetic Menu Board at about 380 USD includes 1,032 characters, which reduces printing or reprint fees over time.

Budget for graphics. Signs arrive blank, so plan a modest line item for local vinyl decals from a signwriter.

Factor installation. Many George & Willy signs include mounting hardware, which can reduce labor time.

When comparing outdoor sign materials, look at expected years of service, maintenance time, and how easily the surface accepts new decals or lettering.

Sustainability and environmental considerations

Material choice affects footprint and maintenance over time.

Aluminum is widely recyclable and retains quality through multiple cycles, a strong point for outdoor sign materials that may be refreshed as brands evolve.

Powder coating is a durable finish with low volatile organic compound output compared to many liquid paints, and it extends service life when handled and cleaned properly.

Sealed and durable materials reduce replacement frequency, which lowers waste over the life of a store fit out.

Sustainably sourced timbers provide warmth and can be used in covered entries or indoors, with scheduled care.

Modular systems with replaceable letters or tiles cut down on disposable printed boards.

Choose outdoor sign materials that minimize corrosion, fading, and waste, then maintain them with gentle cleaners and periodic checks.

Installation and maintenance best practices

Getting the most from outdoor sign materials comes down to solid installation and simple care.

Use the included mounting hardware and instructions, and anchor into suitable substrates with correct fixings.

Clean powder coated surfaces with mild soap and water, avoid abrasive pads that could dull the finish.

Apply decals to clean, dry surfaces and allow proper cure time before exposure.

Inspect brackets and straps seasonally, especially after storms or in coastal regions.

Store portable sidewalk signs indoors after close for longer finish life.

Planning facts that save time

Orders typically process in 1 to 2 working days.

Express target delivery is 1 to 5 working days, economy is 3 to 7 working days.

US orders ship via UPS from Arizona and South Carolina.

Canada orders ship via DHL, EU and UK from the Netherlands, Australia via AusPost, Direct Freight, or DHL, and New Zealand via NZ Post or DHL.

Duties and taxes are included for most markets with DDP, Norway ships DDU.

Free shipping in the US on orders over 400 USD was advertised at the time noted in the brief.

A frame sign weighs about 8.8 lb and folds for storage.

The Magnetic Menu Board includes 10 rails and 1,032 magnetic letters.

The Menu Board with tiles includes 510 reversible tiles, black on one side and white on the other.

All products include a two year warranty for faulty workmanship and materials in normal use.

There is a 100 day change of mind return policy on full price items, sale items are final sale.

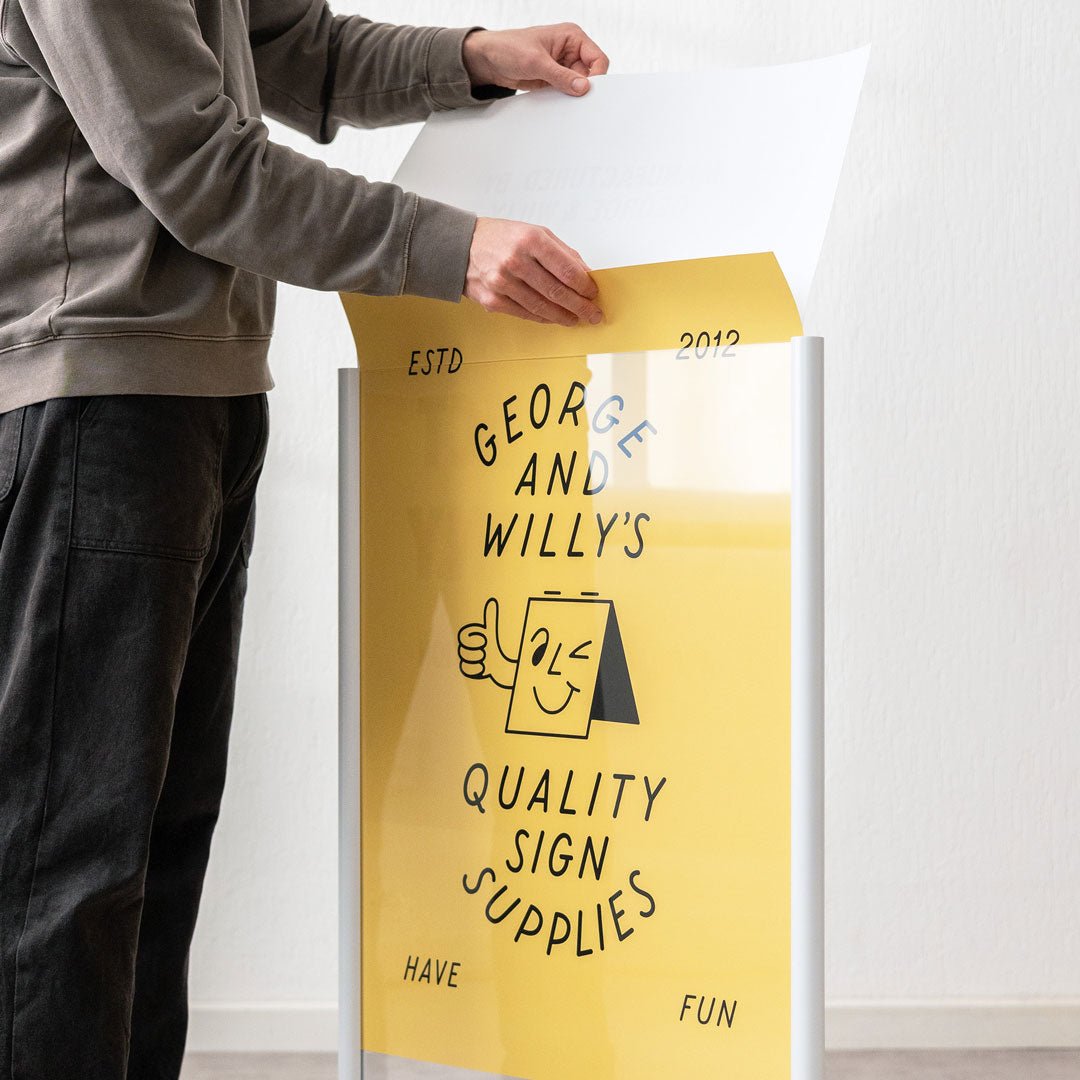

Signs arrive blank, custom logo application is done locally with vinyl decals. For ready made kits, visit George & Willy.

These practical details help teams schedule installs, coordinate graphics, and keep outdoor sign materials looking new.

Conclusion, the best outdoor sign material depends on your needs

There is no single winner for every location. The best choice blends climate, change frequency, mounting conditions, and brand feel. Powder coated aluminum and steel excel for most storefront applications, while changeable letters and tiles keep communication nimble. When you weigh cost against lifespan, choose outdoor sign materials that simplify updates and reduce maintenance. For well designed, ready to install hardware that fits hospitality and retail, explore George & Willy and get your storefront looking intentional.

FAQ, Outdoor sign materials

Q: What outdoor sign materials last longest near the coast

A: Powder coated aluminum and stainless components are strong picks since they resist rust in salty air. Regular rinsing with fresh water helps any finish.

Q: What is the easiest way to update prices without reprinting

A: Choose magnetic letter rails or tile menu systems. The Magnetic Menu Board includes 1,032 characters, which makes quick price changes simple.

Q: Are light box signs suitable outdoors

A: Yes, look for aluminum housings, outdoor rated LEDs, and sealed faces. George & Willy offers round and other cabinet styles with mounting hardware included.

Q: Can I get custom logos printed by the manufacturer

A: George & Willy ships signs blank. Most customers add vinyl decals locally through a signwriter, which keeps lead time short.

Q: How do I budget for outdoor sign materials

A: Compare initial price, expected lifespan, and maintenance. For reference, portable sidewalk signs often range from about 420 to 680 USD in the examples noted, while light box signs start around 680 USD.

Q: Do you ship quickly for openings and relaunches

A: Orders usually process in 1 to 2 working days. Express delivery targets 1 to 5 working days, which helps teams hit opening dates. You can start planning your kit at George & Willy.

Q: Which outdoor sign materials are most sustainable

A: Aluminum is highly recyclable, powder coating extends service life, and modular menu systems reduce reprints and waste.

Q: What if something arrives faulty

A: Products include a two year warranty for faulty workmanship and materials in normal use. Faulty or incorrect goods are repaired, replaced, or refunded, with return shipping covered.