Custom sign printing is the process of creating unique, branded signage tailored to a business's specific needs—from storefronts and window decals to interior directional signs. Your business sign is more than just a marker; it’s a silent salesperson, a first impression, and a constant brand ambassador. A thoughtful approach to custom sign printing can be one of the most effective marketing investments you make. In fact, studies show that nearly 76% of consumers have entered a store for the first time simply because of its sign. That’s a powerful testament to the impact of good design.

This guide walks through everything you need to know about creating effective business signage, from choosing the right type and materials to mastering the design for a successful custom sign printing project.

Why Quality Signage is a Game Changer

Before diving into the specifics, it’s important to understand why professional custom sign printing is so crucial. A well executed sign does more than just state your name, it actively grows your business.

-

It Attracts New Customers: A staggering 68% of consumers have made a purchase because a sign caught their eye. For local businesses, where about 85% of patrons live or work within a five mile radius, a visible and attractive sign is your primary tool for capturing foot traffic.

-

It Builds Your Brand: Consistency is everything in branding. Using a cohesive style across your signage can increase brand recognition by up to 80%. This familiarity builds trust and professionalism, which can translate directly to your bottom line.

-

It Reflects Your Quality: Customers make snap judgments. Nearly 68% of them believe the quality of a business’s sign reflects the quality of its products or services. A cheap, faded sign can send the wrong message before they even step inside.

Types of Signs: Choosing the Right Canvas

The first step in any custom sign printing journey is selecting the right type of sign for the job. Different signs serve different purposes, and a smart strategy often involves using a combination to maximize visibility for various business needs, from permanent storefront branding to temporary event promotions.

Outdoor Signs to Grab Attention

Your exterior signage is your handshake with the world. It needs to be clear, inviting, and durable.

- A Frame Signs: Also known as sidewalk signs, these are perfect for capturing the attention of pedestrians with daily specials or a welcoming message. They are portable and highly effective for street level marketing.

- Blade Signs: These signs project from the side of a building, making your business visible to people farther down the street. They are essential for locations with heavy foot traffic.

- Storefront Signs: This is your main identifier. Whether it’s a classic round sign, a modern light box, or simple window lettering, it needs to be bold and easy to read from a distance.

Interior Signs to Guide and Sell

Once customers are inside, your job is to guide their experience and encourage purchases. Interior custom sign printing plays a huge role here.

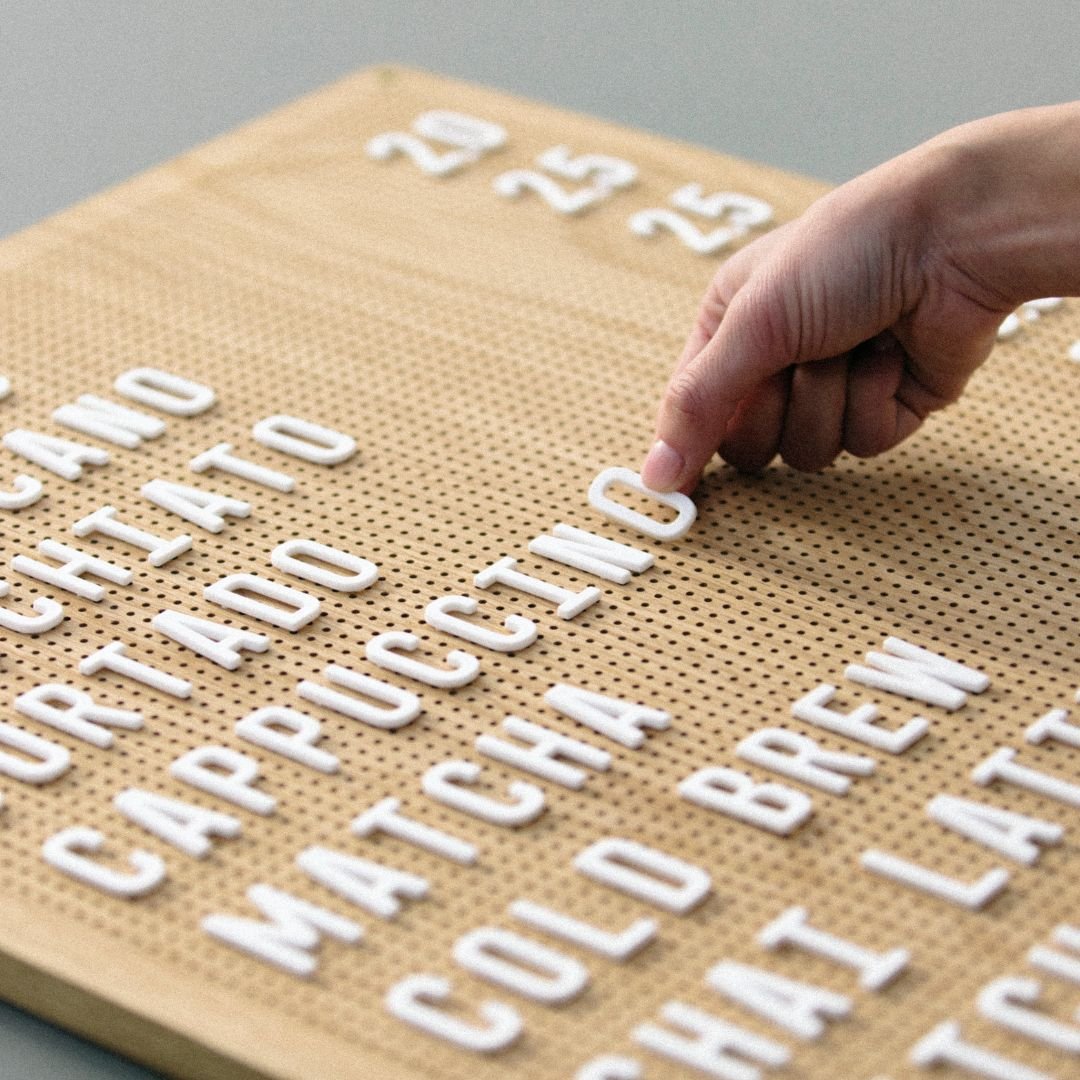

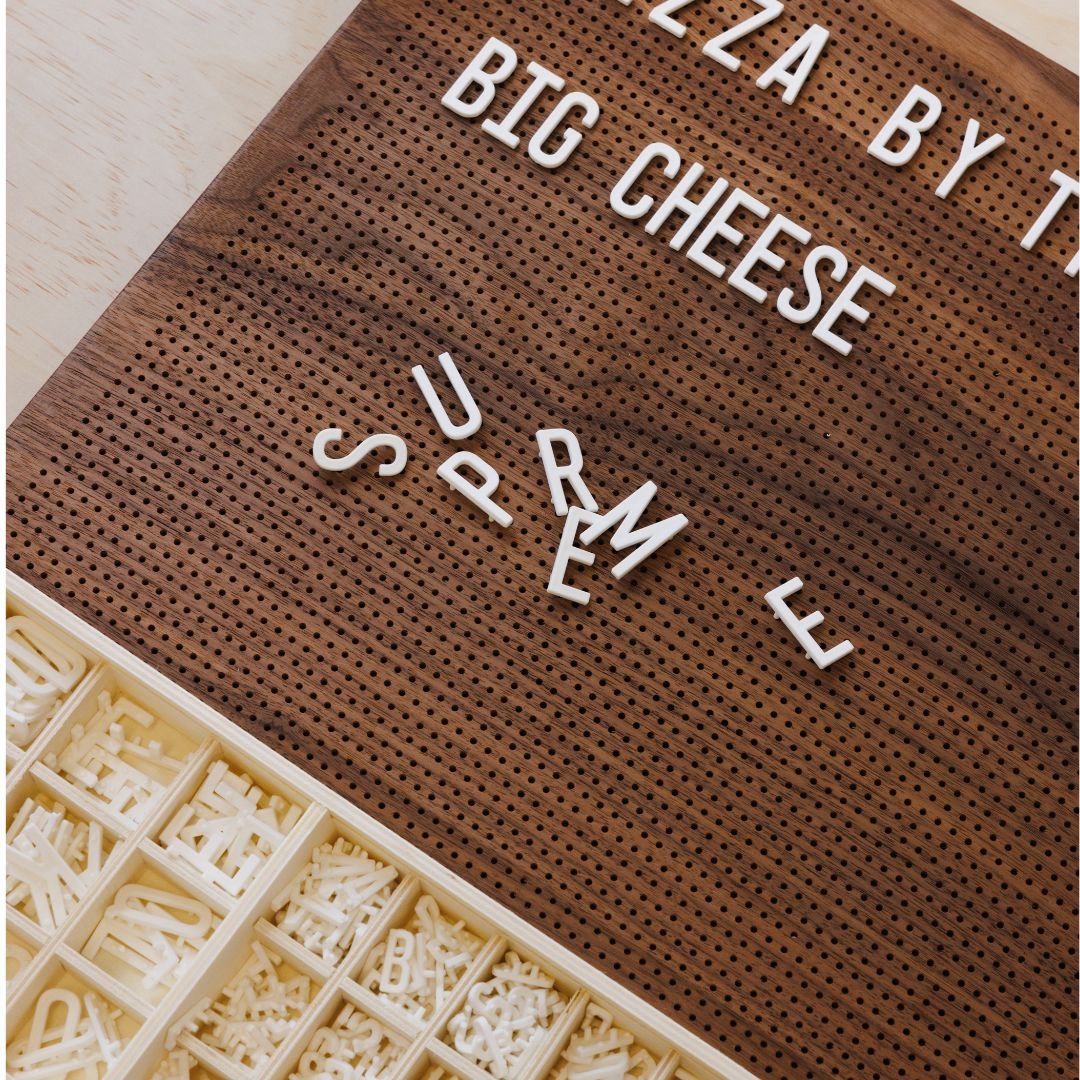

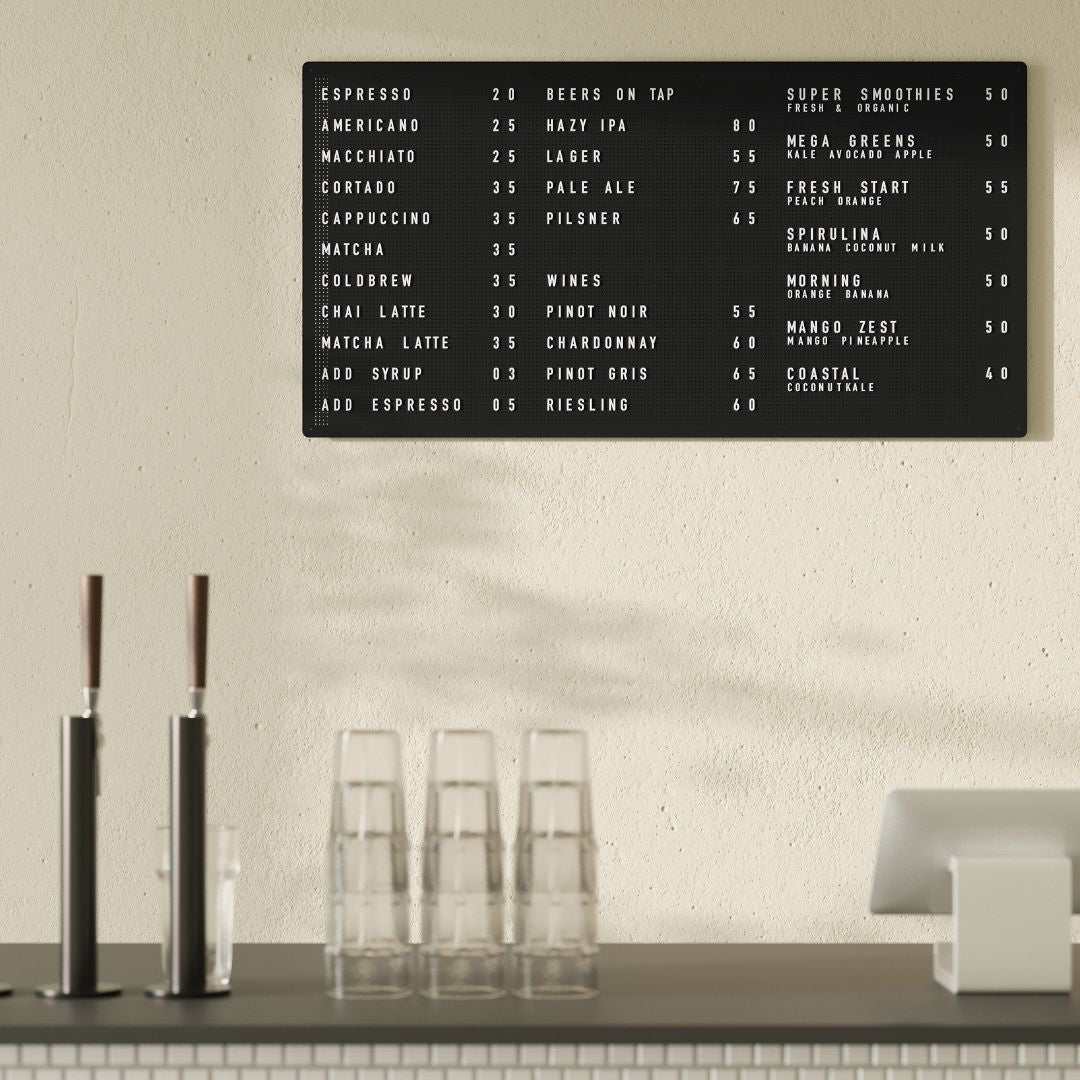

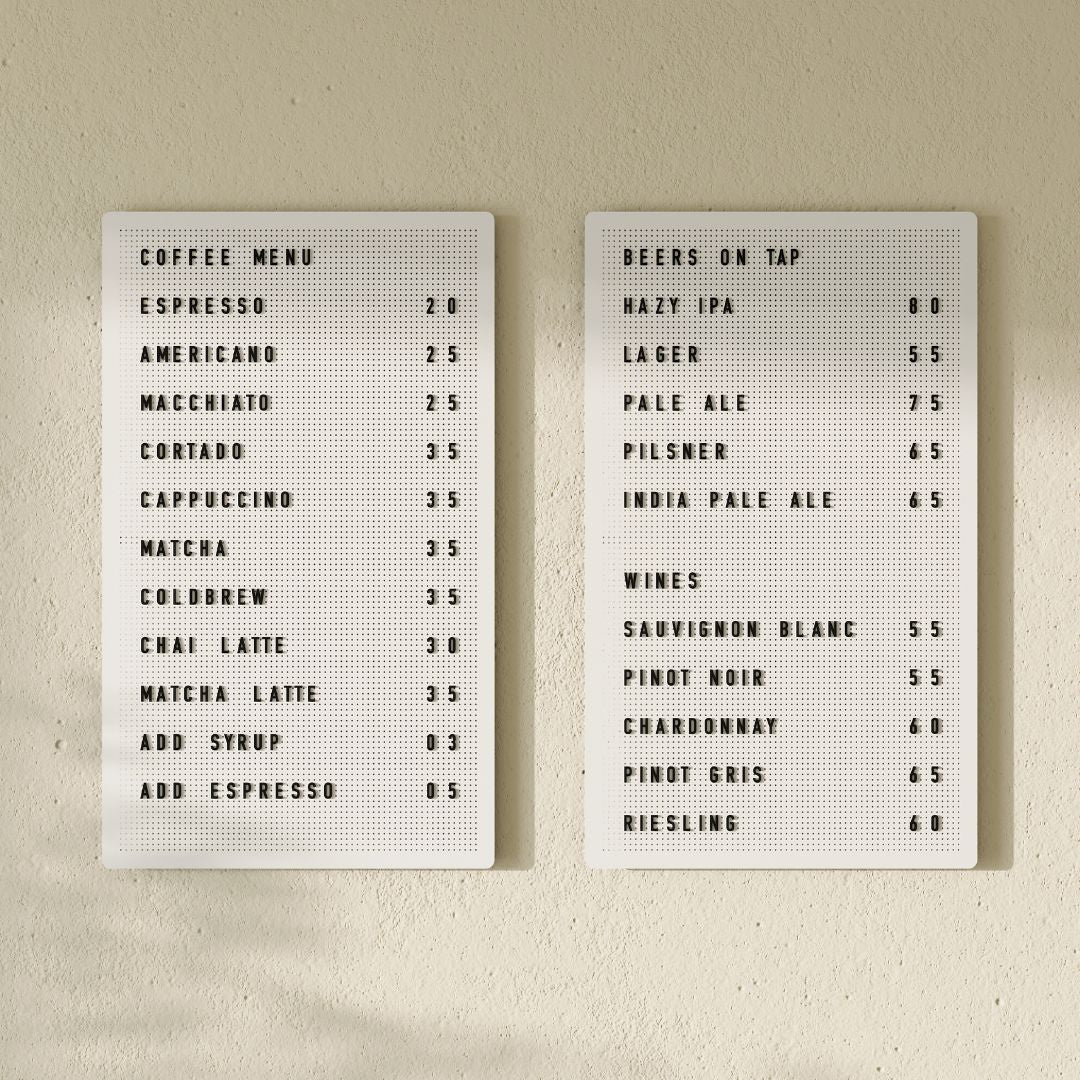

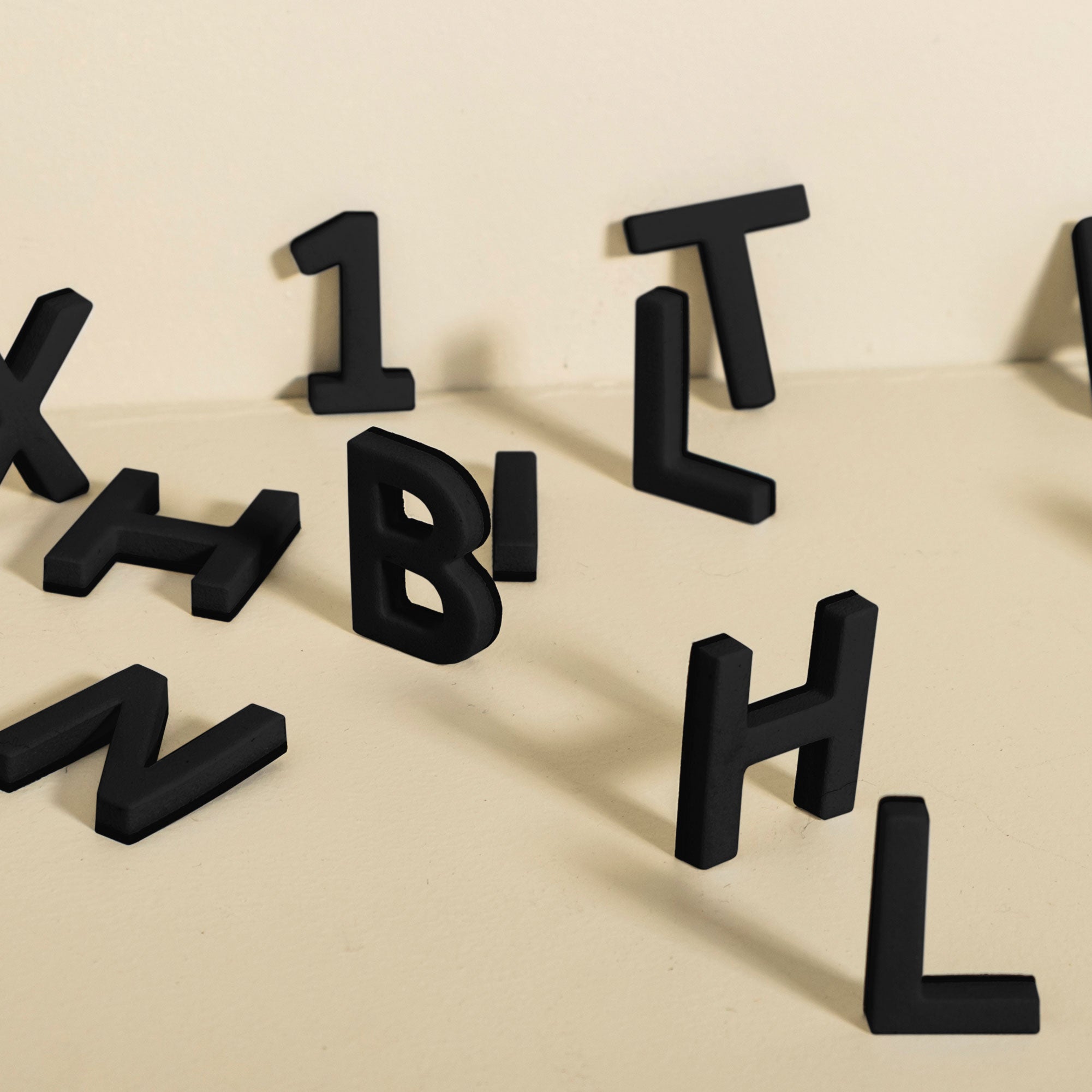

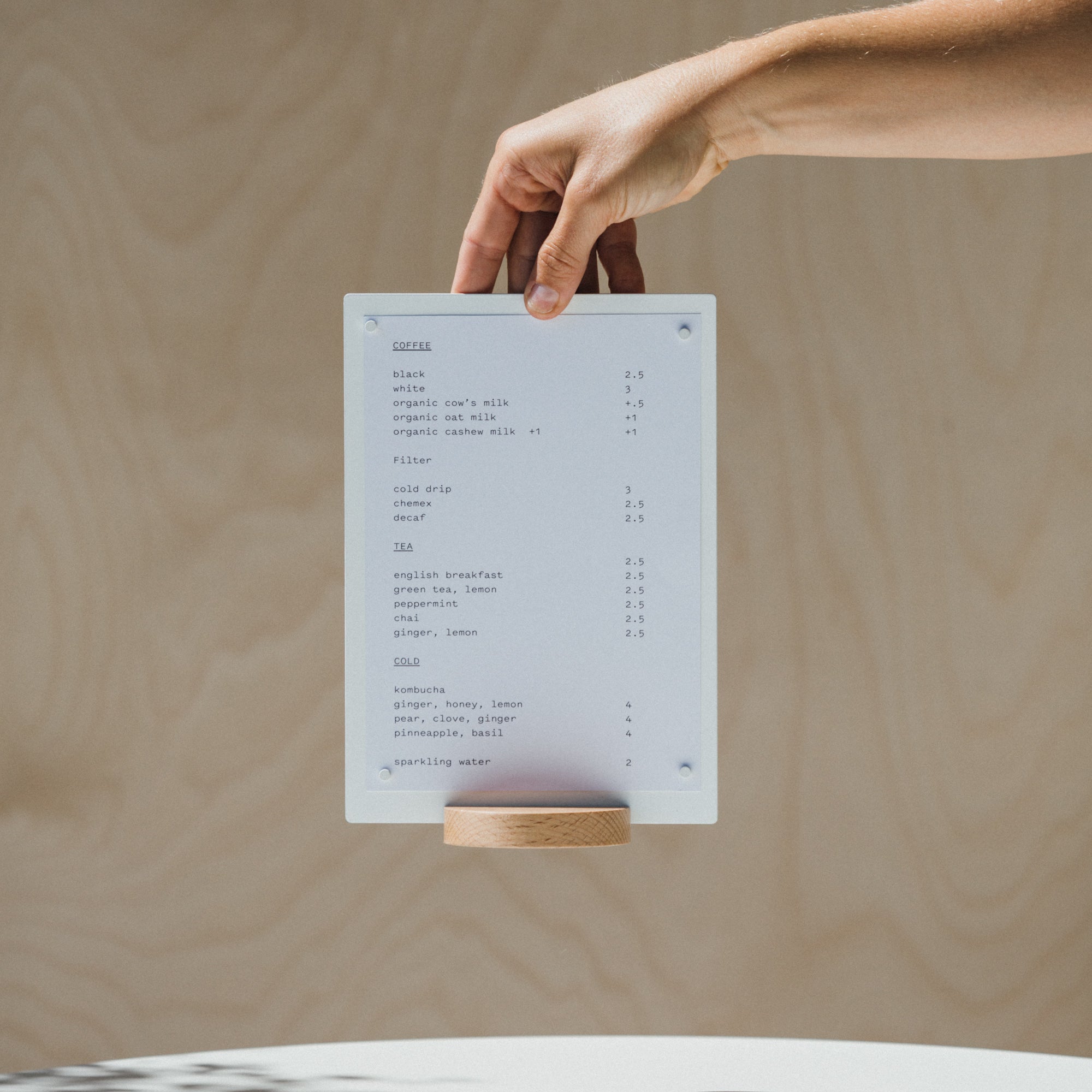

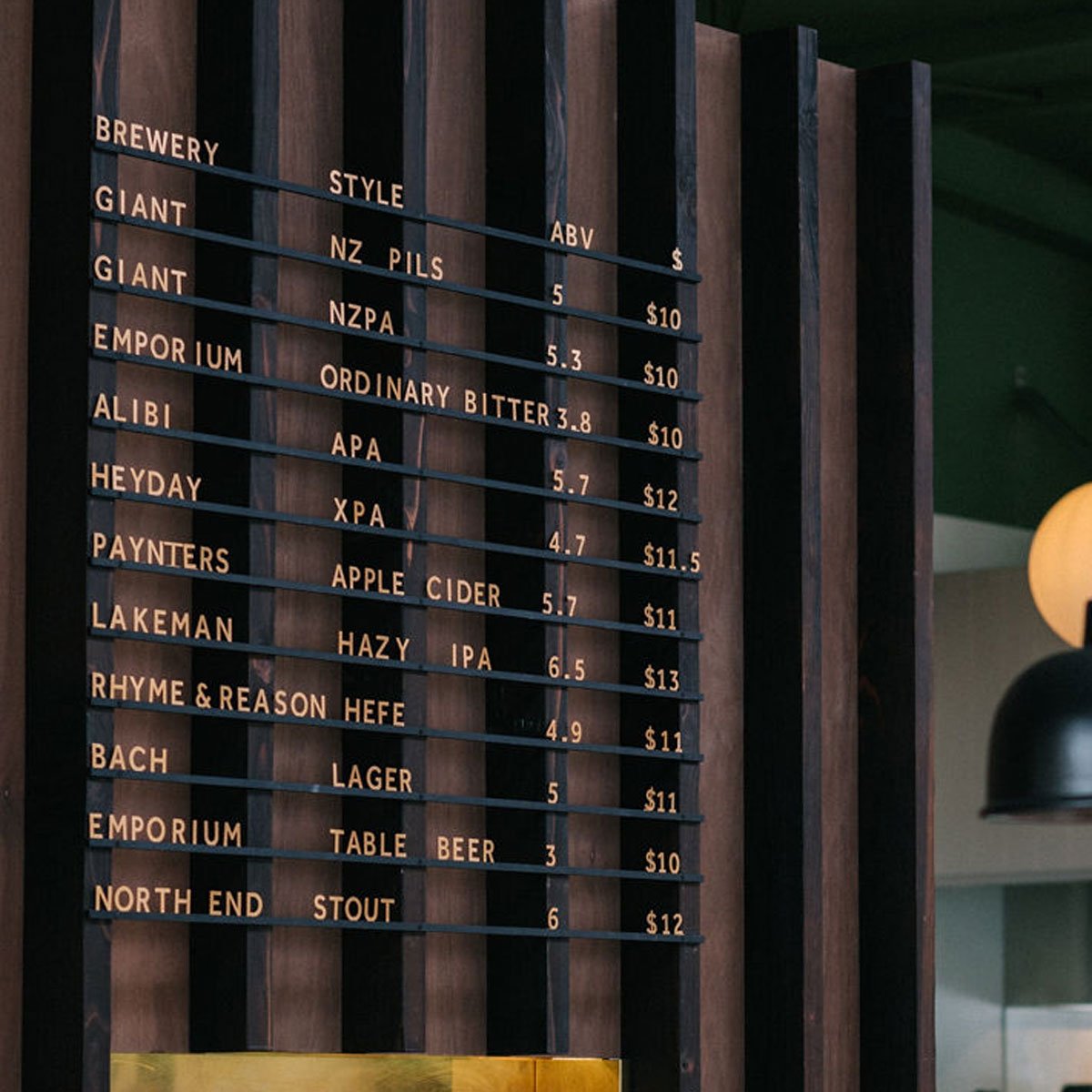

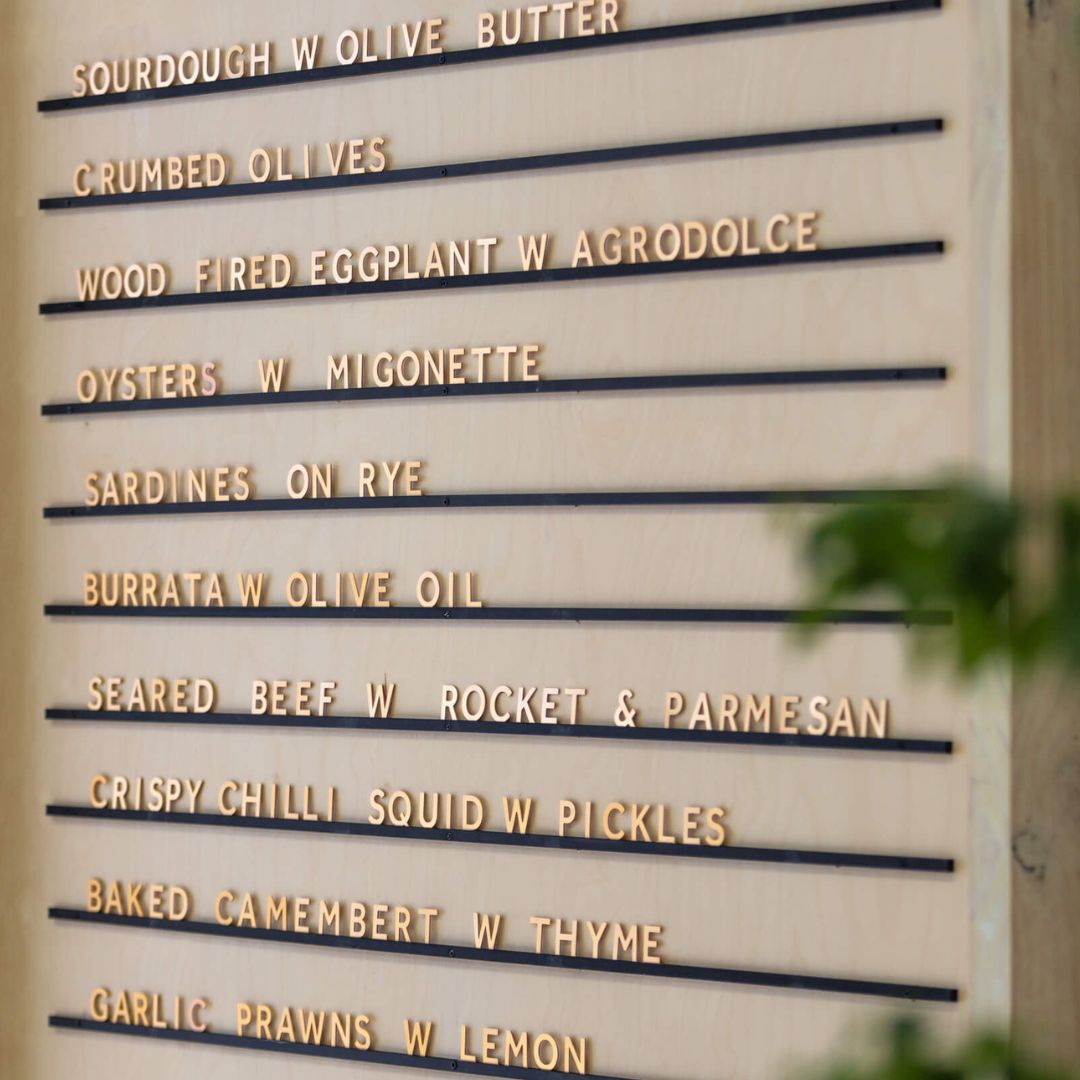

- Menu Boards: For cafes and restaurants, a clear and easy to update menu is non negotiable. Systems like wall mounted letter boards or magnetic menu boards allow for quick changes without the cost of reprinting.

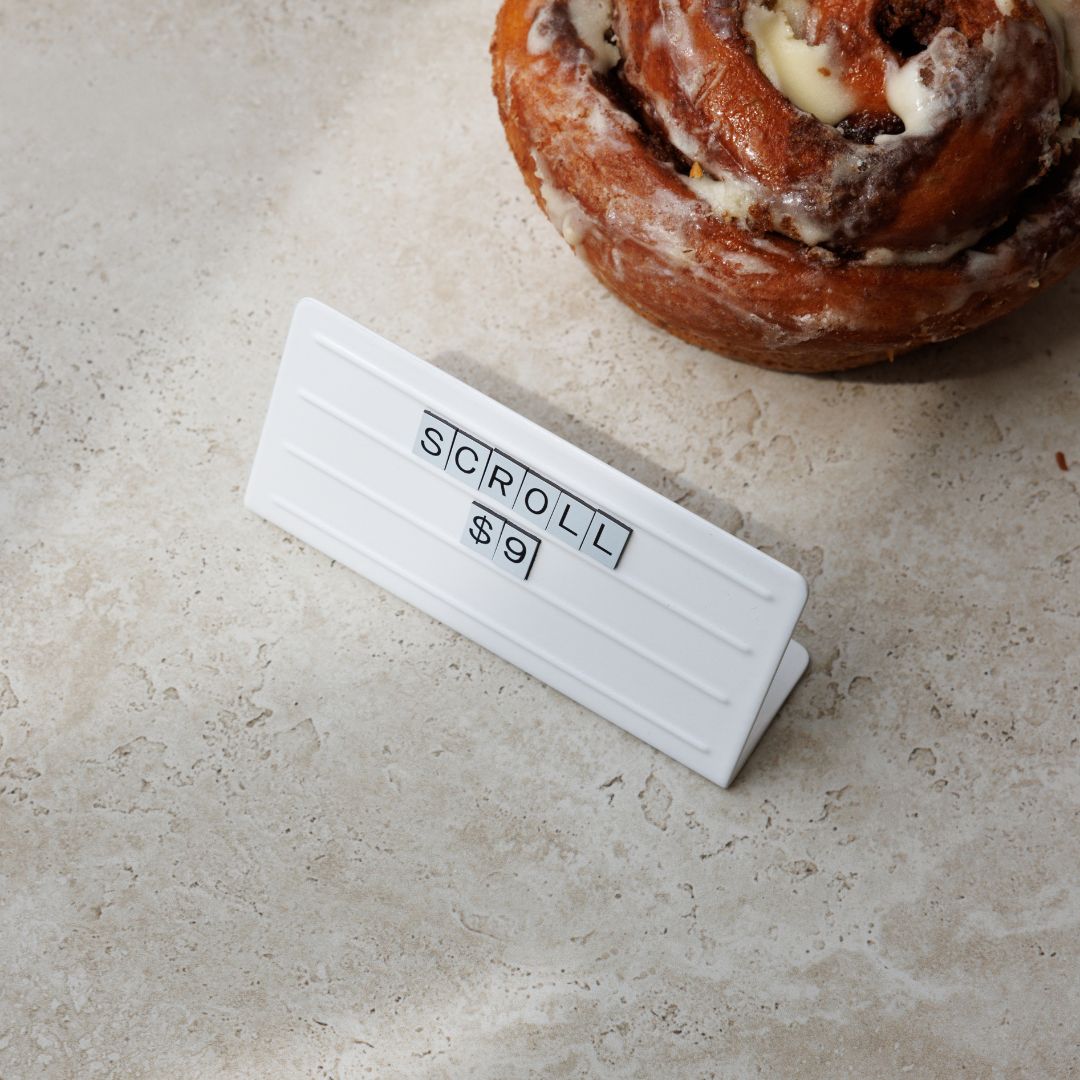

- Countertop Signs: Small signs at the point of purchase can prompt impulse buys and communicate key information. They are perfect for highlighting promotions or new items.

- Wayfinding Signs: These signs help customers navigate your space, directing them to restrooms, specific departments, or checkout counters. Consider a Square Panel Sign for clear department markers.

- Wall and Floor Graphics: Vinyl graphics can transform empty walls or floors into branded experiences, promotional messages, or directional cues, making the most of every surface.

A Deep Dive into Materials and Durability

The material you choose for your custom sign printing is as important as the design. It affects longevity, appearance, and cost. High quality materials not only look better but also last longer, saving you money over time.

- Aluminum: Lightweight, rust proof, and extremely durable, aluminum is ideal for outdoor signs like A Frames and blade signs. A powder coated finish adds another layer of weatherproofing, preventing rust and fading.

- Acrylic: Also known as plexiglass, acrylic offers a modern, glossy finish perfect for sophisticated indoor signs like lobby displays or high end retail branding.

- Vinyl: Highly versatile, vinyl is used for banners, window lettering, wall decals, and vehicle wraps. It’s the go to material for applying graphics to other sign substrates.

- Wood: Best for indoor use or in sheltered outdoor areas, wood provides a rustic, natural, and welcoming feel for businesses like cafes, inns, and boutiques.

- Sustainable Options: Many businesses are now opting for eco friendly materials like recycled acrylic, bamboo, or substrates made from post consumer content to reduce their environmental impact.

Illuminated Signage Options

For businesses that operate at night or want to maximize visibility, illuminated signs are a powerful tool. Options range from classic light boxes, where the entire face of the sign is lit from within, to elegant channel letters, where each letter is individually illuminated. While digital screens offer dynamic content, they come with higher costs and complexity. A well designed, static illuminated sign often provides a more timeless and cost effective solution for brand visibility after dark.

The Custom Sign Printing Process From Concept to Reality

Creating the perfect sign involves careful thought about design, materials, regulations, and application.

Step 1: Nailing the Design and Branding

A sign that can’t be read is just decoration. Clarity is paramount.

- Readability and Sizing: Use legible, bold fonts and high contrast colors. A general rule for visibility is to add one inch of letter height for every 10 feet of viewing distance. For instance, text viewed from 100 feet away should be at least 10 inches tall.

- Color and Psychology: Colors evoke emotion and attract the eye. High contrast pairings (like black on white or yellow on black) are the most legible from a distance. Bright and colorful signage captivates almost 85% of consumers.

- Simplicity and Spacing: Less is almost always more. To avoid a cluttered look, a good rule is to leave 30% to 40% of the sign’s surface as empty space. This allows your message to breathe and be easily absorbed by viewers.

Step 2: Choosing Your Printing Method

The right printing technique depends on your sign’s material, complexity, and intended use.

- Direct to Substrate Printing: Methods like UV flatbed printing apply ink directly onto rigid materials like aluminum, acrylic, or wood. The UV light cures the ink instantly, creating a vibrant and durable finish that’s excellent for outdoor signs.

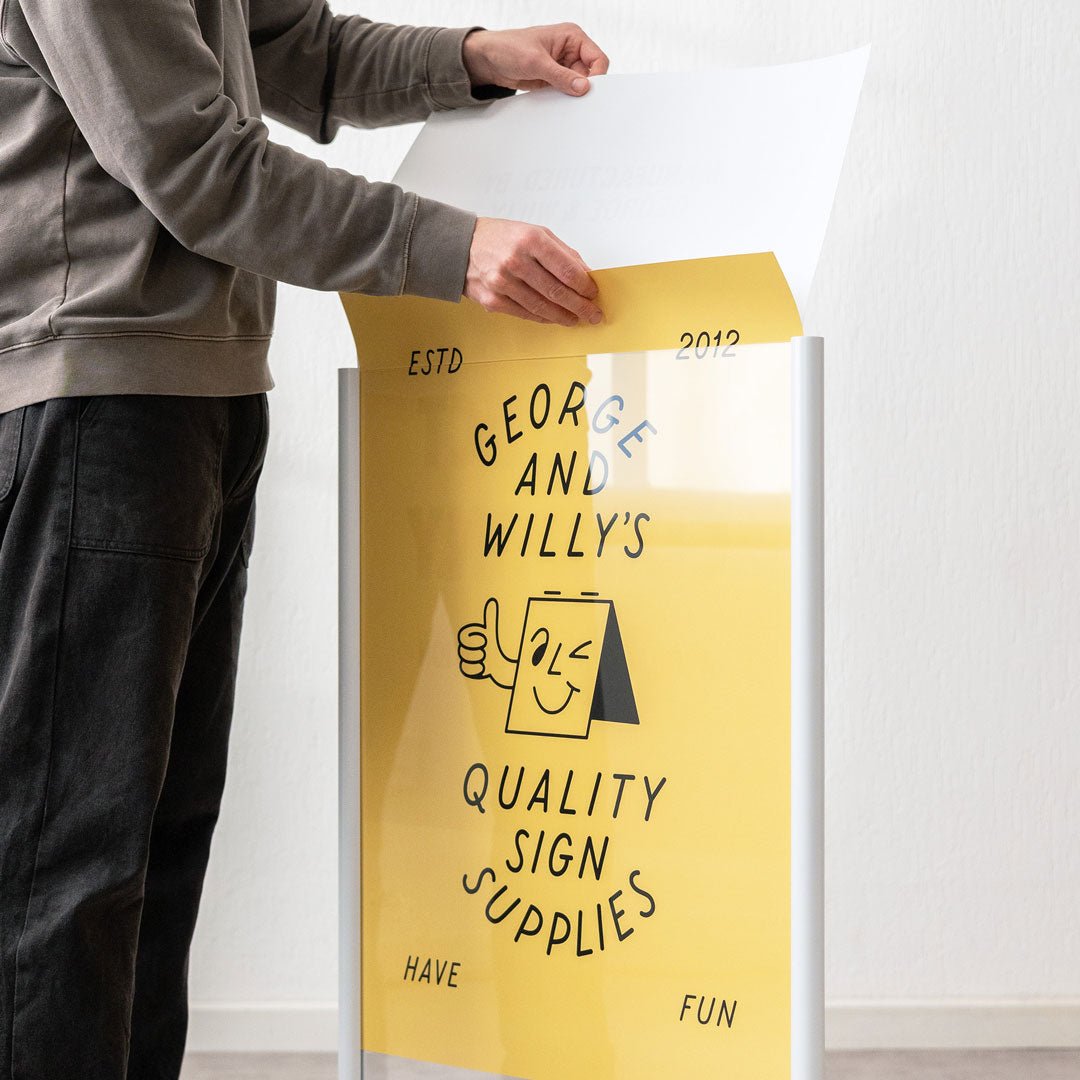

- Print and Apply Vinyl: This is a flexible and popular approach. Your design is first printed onto an adhesive vinyl sheet, which is then carefully applied to a blank sign panel. This method works on nearly any surface and is the standard for adding graphics to high quality hardware.

- Other Methods: For high volume jobs, screen printing offers cost efficiency. Digital printing with latex or eco solvent inks is versatile and offers quick turnarounds for banners and graphics.

Step 3: Prepping Your Files for the Printer

To ensure a crisp, professional result, your design files must be set up correctly.

- File Format: Most printers prefer vector files (like AI, EPS, or PDF) because they can be scaled to any size without losing quality. For image based designs, high resolution raster files (like TIFF or JPG) are needed.

- Resolution: For large format prints, a resolution of 100 to 150 DPI (dots per inch) at the final sign size is typically sufficient.

- Color Mode: Designs should be created in CMYK color mode, which is the standard for professional printing, to ensure the colors on your screen match the final printed product.

- Bleed: Always include a “bleed,” which is an extra margin of your design that extends beyond the final trim edge. This prevents any unprinted white edges after the sign is cut to size.

Navigating Permits, Codes, and Compliance

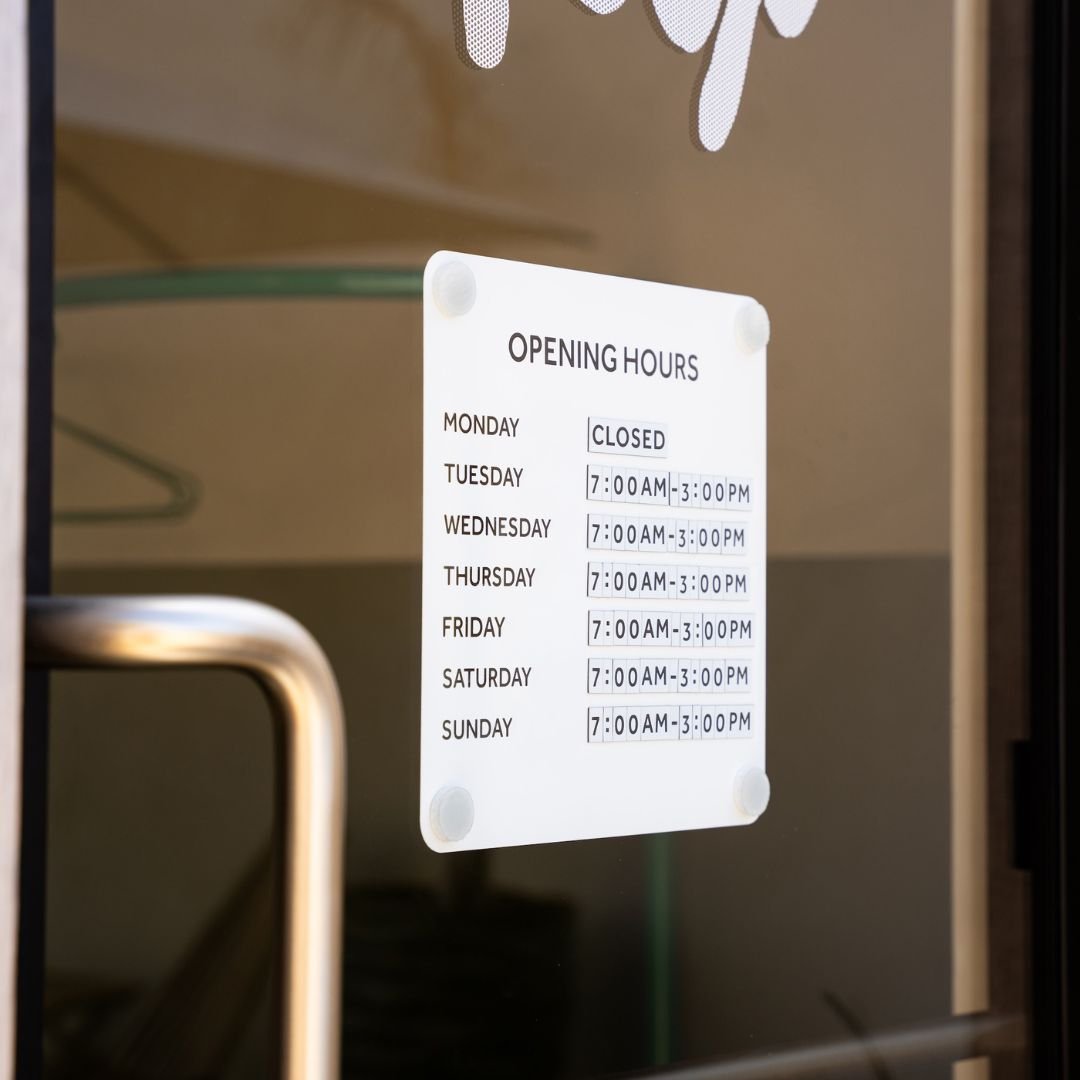

Before installing any sign, it’s crucial to check local regulations. Many municipalities have specific rules regarding sign size, placement, and lighting. Additionally, for permanent interior signs that identify rooms, you must adhere to ADA (Americans with Disabilities Act) standards, which have strict requirements for tactile text, braille, mounting height (typically between 48 and 60 inches from the floor), and non glare finishes.

Installation, Maintenance, and Measuring Success

Proper installation is key to both safety and effectiveness. Mounting methods vary widely, from simple wall screws to professional brackets for blade signs. Once installed, don’t let your investment fall into disrepair. Regularly clean your signs and check for damage.

To understand if your sign is working, track key metrics. Monitor foot traffic before and after installation, or analyze sales data for products promoted on your signage. You can also gather direct feedback by asking new customers how they found you.

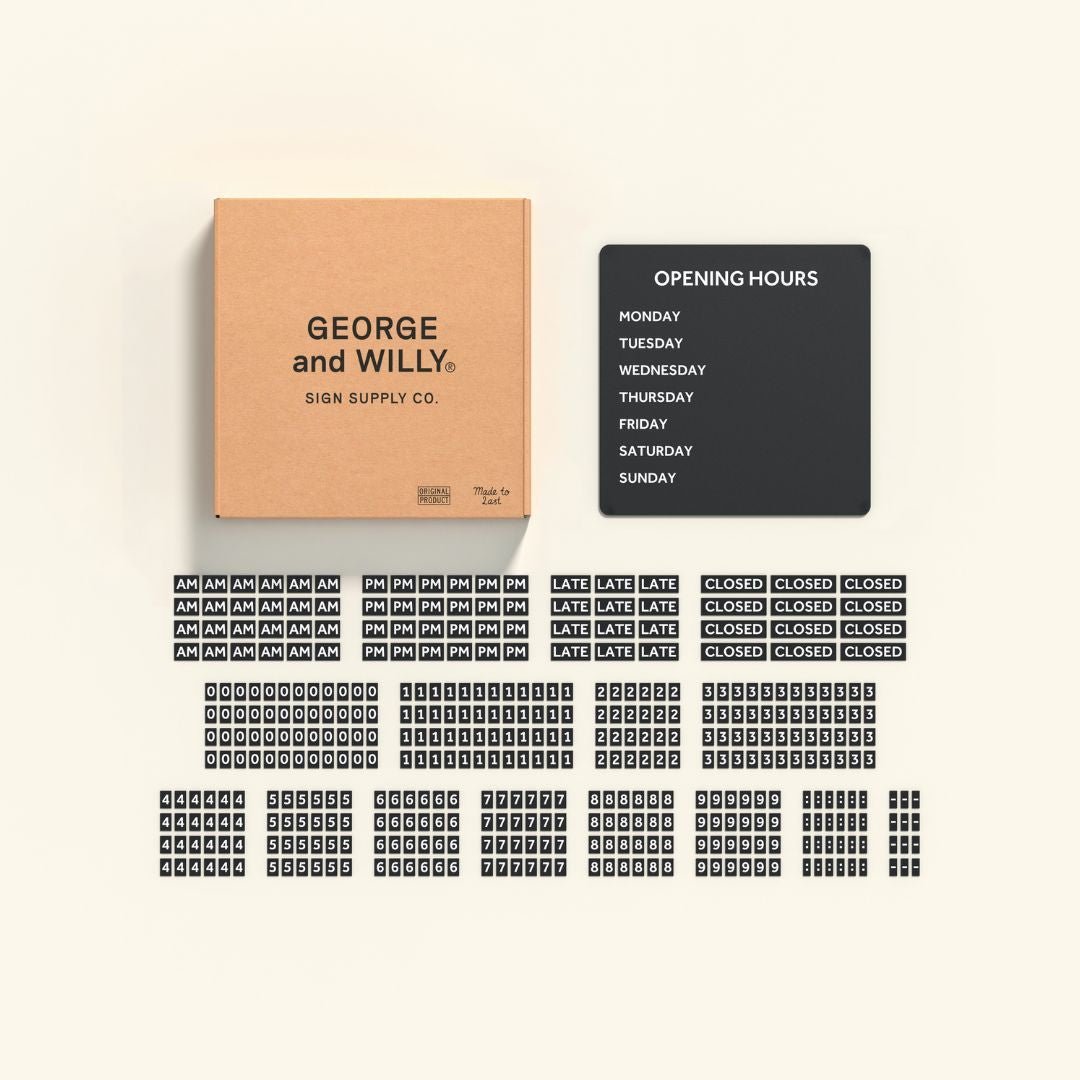

Understanding Costs and Finding a Partner

The cost of custom sign printing can range from under a hundred dollars for a simple banner to several thousand for a large, illuminated storefront sign. When selecting a vendor, look for a partner who is transparent about timelines, warranties, and service terms. A flexible and cost effective strategy is to invest in high quality, blank signage hardware and then partner with a local sign writer to print and apply your custom vinyl graphics. This gives you a premium, durable foundation with a perfectly customized message that can be updated if your branding evolves.

Frequently Asked Questions about Custom Sign Printing

1. What is the best material for outdoor signs?

Powder coated aluminum is an excellent choice for outdoor use. It is lightweight, strong, and naturally resistant to rust and corrosion, ensuring it holds up against rain and sun.

2. How important is readability for a sign?

It is critically important. If customers can’t read your sign quickly and easily, its message is lost. A simple rule is that letters should be 1 inch tall for every 10 feet of viewing distance.

3. How do I prepare a design file for a sign printer?

You should provide a vector file (PDF, EPS, or AI) with all text converted to outlines. Ensure the file is in CMYK color mode and includes a bleed area around the design.

4. Can I update my sign easily?

Absolutely. Many modern signage systems are designed for flexibility. Look for options like magnetic letter boards, peg letter boards, or signs that use changeable tiles like the Menu Board. For printed signs, the vinyl decal approach allows you to update graphics without replacing the entire sign.

5. Do I need a permit for my business sign?

It depends on the sign type and your local regulations. Permanent outdoor signs, especially larger or illuminated ones, often require a permit. Always check with your local city or county planning department before ordering and installing a sign.

6. What makes for good sign design?

Good sign design is a balance of clarity, branding, and simplicity. It uses a legible font, high contrast colors, and enough empty space to be easily read. Most importantly, it is consistent with your overall brand identity.

Your signage is a powerful tool for business growth. By focusing on a clear design, investing in quality materials, and ensuring your message is consistent, you can turn a simple sign into your most valuable marketing asset. To get started, explore our full range of signage designed to help your business make a great first impression.